- Home >

- Fixed Crusher >

- Fixed Jaw Crusher

Fixed Jaw Crusher

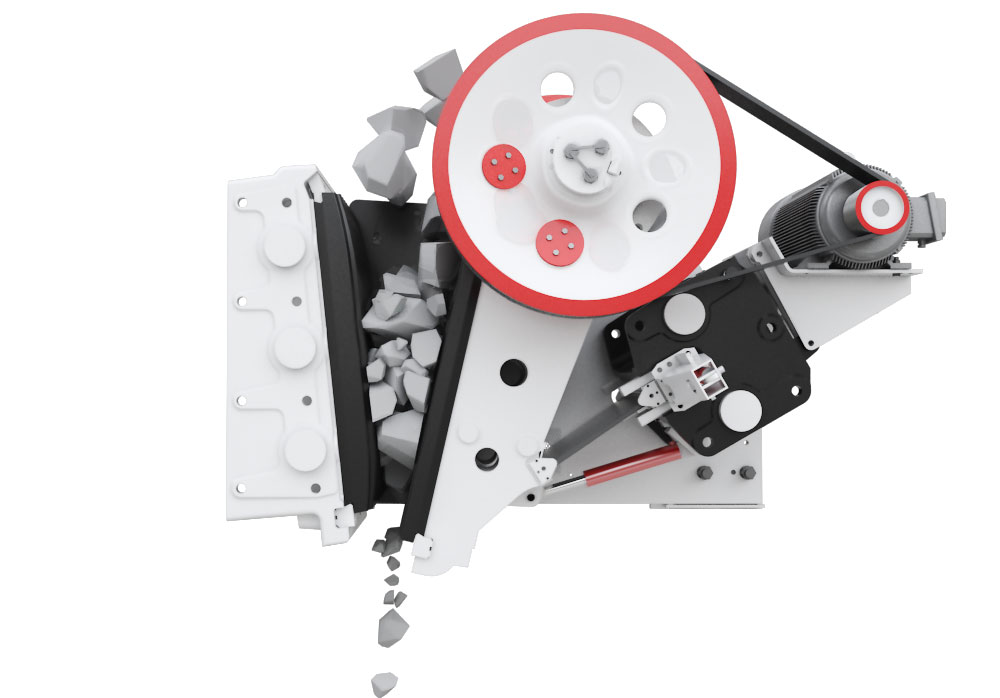

As we all know, a fixed jaw crusher (also called stationary jaw crusher) is widely used in primary crushing for the purpose of crushing bulk and large-sized material into a smaller shape for secondary crushing jaw crusher. In general, a jaw rock crusher can be divided into single toggle jaw crusher and double toggle jaw crusher. The fixed jaw crusher can be also installed on the mobile crushing plant, and then it is called mobile jaw crusher and helpful to such as underground mining and mobile crushing applications. There are different types of fixed jaw crushers such as CJ Euro jaw crusher, HD German jaw crusher, PEX jaw crusher and PE jaw crushers.

![]()

Click and roll the mouse for a full view of panorama

Pinned and bolted & non-welded frame structures & High-quality components

Super-large bearing design & Highly productivity & downtime Reduction

Modularization design & Automation & Hydraulic adjustment discharge opening

Integrated steel frame base & Detachable structure & Steel fabricated subframe

Reliable and Versatile Fixed Jaw Crusher

-Unparalleled reliability

Fixed jaw crusher is a pinned and bolted, non-welded frame construction that provides wonderful fatigue strength. That structure overcomes the inconvenience that the welding rack is prone to stress concentration and is more solid and reliable.

-Excellent performance

Compared with the previous fixed jaw crushers of the same specification, the bearing size is enlarged and the service life is prolonged. The discharge port adjustment is different from the traditional plug-in type adjustment method, using wedges to adjust the discharge port to reduce the labor intensity and downtime.

-Safe Operation and Maintenance

A fixed jaw crusher adopts modularization design to save time and installation costs. Generally speaking, a jaw rock crusher can be installed just in a few days, which minimizing on-site engineering and fabrication. While the real situation is also differernt because the installation of the large one maybe need more time to get it done. Being the most important part of the crushing process, a jaw crusher can realize remote monitoring, adjusting, settings of a feeder, crusher, and conveyor by PLC. Besides, by installation of the hydraulic adjustment discharge port device to make jaw adjustment and maintenance easier.

-Easy Installation & Transportation

The detachable structure is convenient for transportation and installation, especially for underground installation.

The whole fixed jaw crusher machines are placed on the base of the steel fabricated subframe, and the main machine and the base are connected through a short-absorbing pad, which have little influence on the foundation.

Fixed Jaw Crusher Working Principle

The motor drives the belt and the grooved wheel which connects the eccentric shaft. Through the movement of the eccentric shaft, the moveable jaw plate moves up and down. Then the material will be pressed and crushed and discharged from the discharging port.

Four advantages of the Fixed Jaw Crusher

-Environmental protection

Nowadays, due to eco-friendly and low-carbon requirements in many countries, more and more fixed jaw crusher manufacturers turn to design energy-saving and eco-friendly fixed jaw crushers. And actually, they did make great contributions to the world economy, resources conservation, recycling and environmental protection. For example, CJ Euro jaw crusher, a new type of fixed jaw crusher, when porcessing mineral ores, aggregates and coal, etc., adopts advanced dust-removing technology to protect environment without from any floating dust.

-Efficiency and energy conservation

The reason why fixed jaw crusher is so efficient is that the structural design of each jaw crusher parts are more scientific, and the operation is very stable and reliable. So, it can meet users' demand for production in a relatively short time. Thanks for reasonable design with smaller energy consumption, the recycled reasonable use of the remaining jaw crusher crushing force can achieve the perfect crushing effect, thus achieving the goal of energy saving.

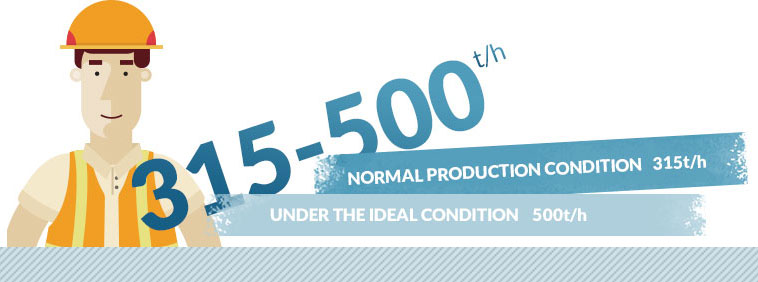

-High yield

The production capacity of fixed jaw crusher plants is 315-500t/h and the production range can be flexibly adjusted according to the actual production demand. The production capacity can be 315t/h under the conventional production state and 500t/h under the ideal state, which is higher than the output of ordinary limestone crusher machines.

-Large crushing ratio

The crushing ratio is an important evaluation index for measuring the fixed jaw crusher machine. The crushing ratio of the fixed jaw crusher machine is the ratio of the raw material size to the accuracy of the finished product. It indicates the extent to which the raw material is reduced after crushing. After the ore is crushed, the particle size becomes smaller. Hongxing Machinery fixed jaw crusher has fine finished products, which leads to a large crushing ratio.

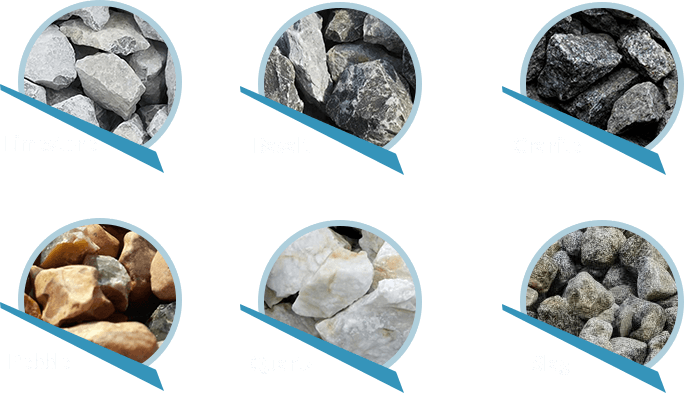

Materials and Application

A fixed jaw crusher is used for coarsely crushing the hardest rocks like limestone, pebble, basalt, granite, quartz, tailings, slag and ores.

Fixed Jaw Crusher Technical Specifications

| Type | Feeding opening size (mm) | Capacity (t/h) | Total power(kw) | Discharging size |

|

CJ Euro Jaw Crusher |

930*580-1500*1300 |

120-1160 |

90-200 | 60-300 |

|

HD German Type Jaw Crusher |

460*720-950*1250 |

50-750 |

55-160 | 45-225 |

|

PEX Jaw Crusher |

150*750-300*1300 |

8-105 |

15-55 | 18-90 |

|

PE Jaw Crusher |

150*250-1500*1800 |

1-1000 |

5.5-355 | 10-350 |

Why Fixed Jaw Crusher

To a certain extent, fixed jaw crusher attracts people by its low price and different models such as mini or small jaw crushers, middle-sized and large-sized stationary jaw crushers. Moreover, it can be customized by manufacturers according to actual demands even suitable for homemade because some rock crusher jaws are easy to buy for customers. In light of the rock crusher machines with low price, small crusher plants are suitable for those production lines with little investment and low requirements for production. For those energy-saving and environmentally-friendly production lines with a large scale and high production capacity, fixed jaw crusher is a good choice for it is highly-efficient, environmentally-friendly and easy to operate and maintain.

Need Some Help?

Our customer service team is here to help you 24/7. We can ship you parts, send field service technicians to your site and answer any questions you have. Whatever you need, we are here for you.

Contact us

Related Blog Posts

- How Does a Small Jaw Rock Crusher Improve Production Efficiency?

- HD German Fixed Jaw Crusher Used in Cement Industry (500TPD)

- 30000MT Jaw Crusher Manufacturing Line for Gypsum

- 5 Keys to Teach You How to Correctly Operate Fixed Jaw Crushers

- Outstanding Performances of CJ Series of Euro Jaw Crusher in Quarrying and Mining

- Differences Between Fixed Jaw Crusher and Impact Rock Crusher