What CJ Series of Euro Jaw Crusher can benefit us?

Convenient to install and less occupied space

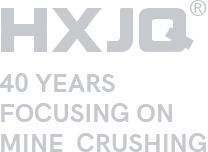

The jaw crusher has always been used as primary crushing equipment in the production line. It requires not only a large crushing strength but also a bearing with a large impact load. Though demanding a suitable working environment, its working performance is very excellent and reliable. CJ Series of Euro Fixed Jaw Crusher can fully guarantee the production efficiency. The continuous advancement of science and technology has led to the development of high-tech mining equipment. The birth of new crushing equipment is a major step forward the direction of safe and easy operation in the process of mineral processing. The CJ Euro Jaw Crusher is a new type of crushing equipment developed with advanced technology on the basis of old crusher machines.

Very durable without bearing problems when running

The frame design of CJ Series of Euro Jaw Crusher abandoned the traditional welding structure, for the detachable frame, connected with cylindrical pins, and then bolted. The base, which is the overall steel frame, is connected with the host by shock pad to improve the stability of its operation. the other difference from the traditional crusher is the position of the motor because the whole machine is an integrated structure. That means the motor base and the host are together, so it’s very convenient for the users to install, has a small footprint and saves space.

It doesn’t take much to operate

More and more industries tend to be automated, which will save a lot of manpower and time. The previous technology is not enough to support the time-saving and labor-saving requirements. However, as the crushing technology tends to mature, the CJ Series of Euro Jaw crusher installs a hydraulic device which can be used when adjusting the discharge port. And the difference between the method of discharge port adjustment and the traditional insert plate type is that the former adopts wedge adjustment which can reduce downtime and labor intensity.

HXJQ CJ Series of Euro Fixed Jaw Crushers tend to be operated easily

CJ Series of Euro Jaw Crusher— Leading the development of the quarrying industry

As the basic material used in the construction process, sand and gravel are often used as concrete raw materials in the field of housing and infrastructure construction. Aggregate is also an important part of road and railway bed. With the rapid development of the economy and the gradual improvement of people’s living standards, the demand for sand and gravel has continued to increase in recent years. The aggregate consumption is mainly based on cement applied in the production of cement products, concrete, and mortar, gravel and asphalt concrete for roadbed.

Therefore, infrastructure construction is the basis for driving the needs of the entire construction machinery industry. Take China as an example, during the “Twelfth Five-Year Plan” period, the further acceleration of China’s high-speed railway construction, the increasing demand for clean energy, and the accelerating urbanization process will bring the most direct benefits to the construction machinery industry. So, the crushing machines are indispensable in the sand and gravel industry.

CJ Series of Euro Jaw Crusher crushes cobblestone

Cobblestone or pebble, whose chemical composition is silica, has strong abrasion resistance, good corrosion resistance, and high hardness, and they belong to hard stone. Pebbles contain other valuable elements, such as an iron oxide or manganese, copper, etc., the crushed cobblestone is widely used in construction, so they can also be used as an ore. Through the crushing operation of CJ Series of Euro Jaw Crusher of HXJQ Machinery, the pebbles can be fully utilized.

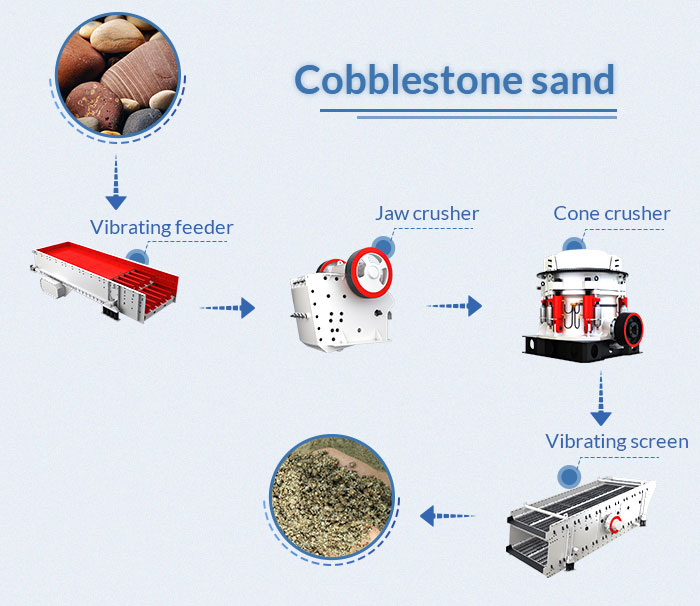

Introduction of sand making process from cobblestone

The crushing process of the cobblestone should be designed reasonably. When considering the investment cost of the crushing project, the cost of the production line must be considered. In the crushing operation, the wearing rate of the jaw plate, the hammer and the impact plate is very high. Therefore, in the design of the crushing process, the crushing way of the lamination is selected as much as possible to reduce the wear of the wear parts.

Typical laminating equipment is a two-stage jaw crusher or one jaw crusher with a cone crusher. If the customer has higher requirements on the final stone size, it can be configured with an impact rock crusher to shape final material, thus forming a three-stage crushing process configuration. Though three-stage crushing will inevitably lead to higher investment costs for the project, but for the long-running stone plant, the three-stage crushing is very significant for the reduction of production costs. For the more difficult-to-break stone materials such as pebbles, a two-stage crushing process of a CJ Series of Euro jaw crusher and an impact crusher can also be used.

Crusher machines used in sand making process

An integral part of the mining industry— CJ Series of Euro Jaw crusher

In the past, China was too bold in mining mineral resources, causing serious pollution and mining waste. The main reason is that the equipment technology used is not advanced enough to meet international environmental protection technology standards. Experts pointed out that in order to curb the occurrence of such contradictions, mining machinery enterprises must actively develop high-performance equipment in accordance with market demand, which is the basis of current enterprise development.

In the future, new mines must all meet the requirements of green mine construction. The mines being produced must be upgraded and gradually meet the standards.

https://www.newsecuritybeat.org/

At present, transforming into a green mine has become the wind vane of mining development. As a mineral resource with the largest amount of exploitation, the widest distribution area, and the most serious environmental protection problems, the construction of green mine directly reflects the overall promotion of “green development” in the mining industry. In the future, green development will become a new theme in the development of sand and gravel mines, and various policies and standards for the construction of green mines will be introduced. While the jaw crusher is one of the most widely used equipment for primary crushing in the mining industry.

Due to the important position of the jaw crusher, its performance directly determines the quality of the entire ore processing. HXJQ Machinery has increased its investment in science and technology, focusing on high-efficiency environmental protection, waste-water recycling, energy saving, dust prevention and noise reduction, and other core technologies related to ecological environmental protection to actively promote the green transformation of aggregate mines. As you could see, The CJ Series of Euro Jaw crusher is one of many achievements.

http://www.chinagoldintl.com/operations/jiama/

CJ Series of Euro Jaw crusher crushes copper ore

Copper ore refers to the general term for copper-containing natural mineral aggregates that can be utilized. Copper industrial minerals are natural copper, chalcopyrite, beryllium copper, azurite, malachite and so on. More than 280 copper-bearing minerals have been discovered but only 16 are mainly used.

The development of manufacturing is inseparable from the use of copper. According to a report published by the American Copper Development Association (CDA), after entering the 21st century, copper is widely used in the electrical and electronic industries and is widely used in mobile phones and computers. The manufacture of electronic products accounts for more than half of the total consumption.

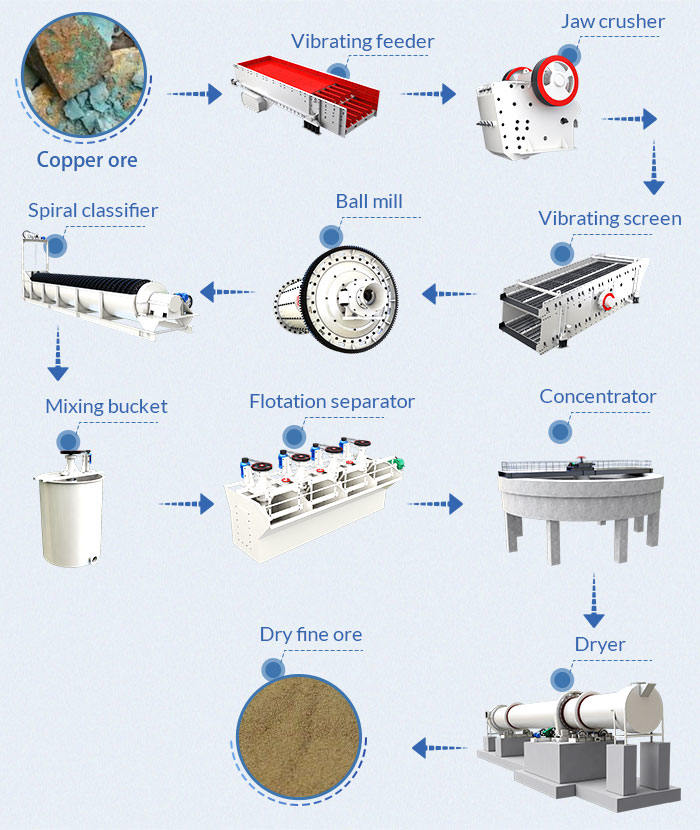

The copper ore production process

The copper ore mainly includes three processes of crushing, grinding and beneficiation. In the process of crushing, the three-stage closed-circuit crushing which suits for high-hardness copper ore can complete the ore crushing and partial dissociation work, thereby improving the subsequent grinding efficiency. During the grinding process, the second-stage closed grinding is efficient, which can give the copper ore a fully grinding. In the beneficiation process, the relatively successful new process that has emerged in recent years is representative of the mixed flotation process.

In copper ore mining sites, large pieces of copper ore are transported from underground mines by excavators and loaders to crushing lines, then to vibrating feeders via silos. The vibrating feeder evenly sends material to CJ Series of Euro jaw crusher or the portable jaw crusher for primary crushing (reducing the bulk raw ore into small pieces). After the coarsely crushed copper ore is sieved, it is sent by belt conveyor to a cone crusher for secondary and fine crushing (breaking small pieces of ore into fine size particles).

9 Outstanding performances of CJ Series of Euro Jaw crusher

- The crushing chamber is deep and has no dead zone, which improves the feeding capacity and output.

- The crushing ratio is large and the product granularity is uniform.

- Adjustment of the gasket-type discharge port is reliable and convenient.

- Adjustment range is large, which increases the flexibility of the device.

- The lubrication system is safe and reliable, the parts are easy to replace, and the equipment maintenance is simple.

- The machine structure is simple, the work is reliable, and the operating cost is low.

- Equipment energy saving: single machine energy saving 15% to 30%, system energy saving more than double.

- The discharge opening has a large adjustment range to meet the requirements of different users.

- Low noise and less dust

Thanks to simple structure, convenient maintenance, and long-term use, CJ Series of Euro Jaw crusher has always played an important role in the current construction.

Literature extracted from:http://www.cnki.com.cn/Article/

http://www.zgss.org.cn/xueshu/jiaoliu/5158.html