- Home >

- Portable Rock Crusher >

- Tracked Crusher

Tracked Crusher

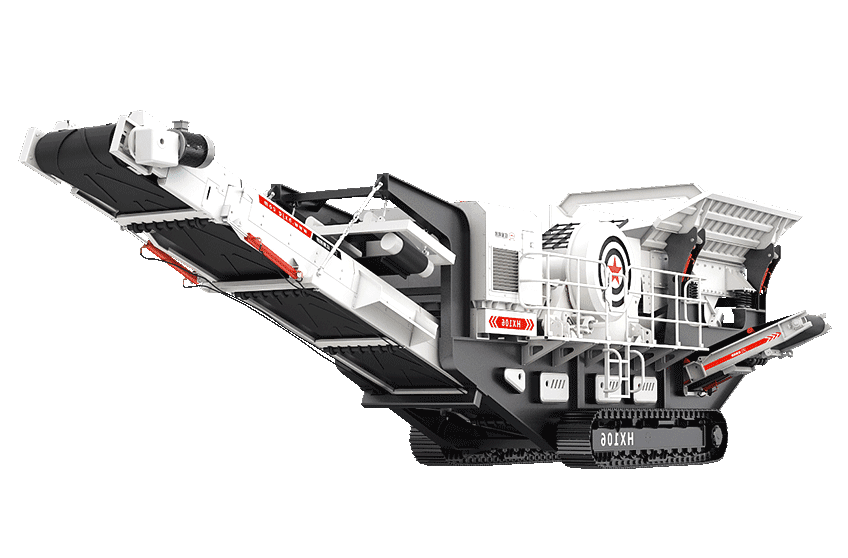

Tracked crusher is a stable, safe and reliable crawler type of crushing and screening machine which is excellent for recycling construction waste, asphalt, bricks and concrete and other demolition materials, as well as medium-hard natural ore and glass. Transport size, weight, and compact construction make transportation even more convenient, which give the mobile crusher great flexibility.

Engine silent box &Spray system to suppress dust& Pulse dust removal device

Control panel& emergency stop button &wireless remote control

Diesel generator set power generation & Vehicle-mounted installation & low labor consumption

Flexible Movement &Small Size & Small Footprint &Hydraulic System

Outstanding performance of tracked crusher plant

-Convenient Transportation

Track-mounted impact crushers are loaded by a light loader is a movable crushing device consisting of three systems like feeding, crushing and conveying. Due to small in size and less occupied space, a kind small portable rock crushers can easily cope with narrow working conditions and crawler walking will not damage the ground. Tracked rock crusher of HXJQ Heavy Machinery is excellent in both power matching and structural design. The crawler crusher is driven by the hydraulic systems so as to achieve smooth walking and adapt to a range of complicated field conditions. It can be widely used in mining, quarrying, highway and bridge construction, etc. There are different types of tracked crushers such as tracked fixed jaw crushers, tracked impact rock crushers, tracked cone crusher machines, tracked vibrating screen crushers, and some other track-mounted crushing equipment.

-Easy installation and maintenance of tracked crusher

- The tracked rock crusher relies on the diesel generator set to generate electricity. It not only gets rid of infrastructure installation at the complex site but also reduces the working hours. The tracked mobile impact crusher also greatly enhances the flexibility of the equipment transition, thus significantly reducing the transportation cost.

- Observation and maintenance of the door is set to check for worn parts.

-Safe and Reliable Crushing Operation of mobile crushers

- Fast setting and safe operation: hydraulic lock hopper on the ground.

- The control panel is placed in the electric control cabinet and located on the right side of the tacked- mounted crusher (driving direction - the discharge belt is in front) and is covered in the lockable protection device.

- Operate and control the screening plant and stone crusher plant.

- Emergency stop button (in case of emergency, the crushing and screening plant can stop the --rock equipment operation by pressing the emergency stop button, and the diesel generator unit will stop working)

-

The wireless remote control:

When running, the wireless remote control is used to control the track; In the crushing mode, the wireless remote control is used to control the feeding. In the wireless remote operation mode with loading, the emergency stop device on the remote control device can work at any time. If the wireless is suddenly interrupted during the operation of the rock equipment, the tracked crusher will stop the operation to ensure safety, and then a dangerous emergency stop is reported immediately.

-High efficiency and environmental protection

- The tracked crusher is continuously optimized and equipped with an engine silent box to isolate noise. The iron remover separates the iron-containing part from the material. The design of spray system is to suppress the dust generation.

- During the working process of the track-mouted crusher, a pulse dust removal device is added to assist the dust collection process, and the dust removal rate is high to 99%. Besides, the corresponding anti-smashing system teams up with the dust removal device to achieve multiple protection.

- The spray atomizing device is added to the feeding opening, the discharge port, the conveyor, which can effectively control the pollution. Therefore, it makes environmental protection easier and production safer.

How does the tracked crusher plant work?

-Working principle of mobile rock crushing and screening equipment:

The materials to be crushed directly enters the feeding hopper.

The vibrating feeder transports the material from the hopper to the vibrating screen, and then enters the impact rock crusher machine through the chute.

The qualified material after being crushed is directly unloaded through the under-belt for storage or unloading into the on-site conveyor.

The broken non-standard material is returned to the hopper through the lifting belt.

-Classification of HXJQ machinery tracked crusher machine

The tracked crusher can be divided into four series: primary crushing, secondary crushing, and tertiary crushing.

The primary crushing usually proceeds by the fixed jaw crusher machine and high-yield hammer crusher machine, mainly processing large pieces of materials of 30 cm or larger.

The secondary crushing processes medium-sized materials of 30 cm or less, and the main crushing machine tends to be hydraulic cone crusher machine and impact rock crusher.

Sand making machine and tertiary impact rock crushers are the main crushing equipment in the third-class crushing, processing fine aggregates.

The screening station is a separate series that selects the number and size of the screens based on the type and output demands of the customers.

Review of tracked crusher machine

The tracked mobile impact crusher is used in the primary or secondary crushing stage. It can be flexibly moved in different locations. So the tracked mobile crusher and its power transmission combines diesel and hydraulic drives. Vibrating feed machine transfers oversized blocks from quarry to impact rock crusher, thus reducing them to the needed size while the smaller materials fall directly onto the main conveyor then being further discharged during the crushing process. In addition, because it can be equipped with a double-layer or multi-layer vibrating screen, the feeding machine, and conveyor. The tracked crusher for sale can produce a category of products. Tracked impact crusher is one of the most common products used in recycling applications, including concrete, asphalt and demolition waste. It is also the perfect choice for limestone in quarry applications.

The mobile crushing station can be set directly on the mining mountain so that a large number of truck transportation can be excluded and can be widely used in different operation and production projects in the mining industry. Besides, there are also a lot of mini tracked crushers for small production demands, which means the frame of the tracked crushers can be configurated mini crushers like mini jaw crushers, mini cone crushers, etc.

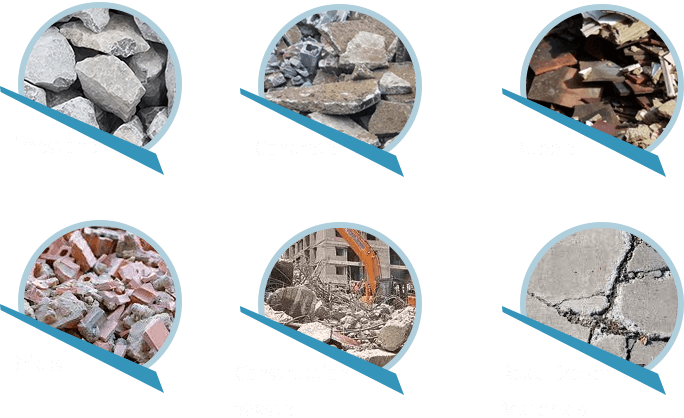

Materials and Application

The China Hongxing tracked impact crusher for sale can crush material like concrete(so it also called concrete crusher), limestone, rubble, bricks, gold mine, ore, construction waste, road broken materials, natural stone. And its production capacity is up to 180 t/h, which depending on the feed machine, set breaking gap width and final particle size. Besides, the final particle size is less than 31.5mm , which depends on the mesh size of the screen.The working ability of the mobile impact crusher mainly depends on its physical properties, the material composition, the size information and humidity of the feeding material, equipment settings, the degree of wear of the impact plate, etc. The working model of tracked crushers are a little different from the tracked jaw crusher and cone crusher.

Tracked Crusher Technical Specifications

| Type | speed(m/min) | total Power(kw) | Weight(t) | Capacity(tph) |

|

Tracked cone crusher |

0-20 |

201-268.5 |

40-52 | 100-400 |

|

Tracked jaw crusher |

0-20 |

112.9-141.4 |

38-50 | 300-450 |

|

Tracked impact crusher |

0-20 |

196.8-250.8 |

40-52 | 100-400 |

|

Tracked vibrating screen |

0-20 |

45.5-65 |

28-46.5 | 300-580 |

The powerful mobile stone crushing equipment, combined with these techniques, can be ideal for all crushing process.

-Raw material of tracked crusher plant

Feeding Size: Maximum feed size, no more than 80% of the inlet size of the impact crusher equipment

Crushing strength: It can be used in the primary crushing stage with a crushing strength of 100 MPa and a secondary crushing stage with a crushing strength of 150 MPa.

Mineral material type: impact crusher, capable of processing medium -soft hardness of natural stones such as limestone, dolomite, sandstone and rubble, brick, asphalt, reinforced concrete, and other building residues.

-Crushing ratio of tracked crusher equipment

Crushing ratio: The maximum crushing ratio of tracked crushers (import size/export particle size) depends mainly on the physical properties of the raw materials.The following data is available for reference:

- The crushing ratio of limestone, rubble, and asphalt is about 10:1.

- Which depends on the concrete grade and the reinforced concrete crushing ratio is 10:1 to 15:1.

- If limestone, rubble, bricks, inferior concrete in a closed process (equipped with a final screen and material returning equipment), the rock crushing ratio can be up to 20:1 or higher.

The tracked mobile impact crusher plant is composed of many devices, the host machine contains jaw crusher, cone crusher, and impact crusher. Where there is a need, there is Hongxing Heavy Machinery. To rest assured customers is Hongxing company’s obligatory duty, Whatever you buy crushers or not, Hongxing welcome you to see the portable rock crushers for sale and consult with technical staff for information all the time. Besides, there are also several mining industries cooperating with the company.

Family of HXJQ Machinery Tracked Crusher

Zhengzhou HXJQ independently develops the mobile jaw crusher machine, combining the crawler vehicle chassis with full hydraulic drive. This crawler mobile crusher is not only beautiful in shape, but also has high performance and high yield.

In addition, the China HXJQ mobile jaw crushing station is enough to provide unparalleled crushing performance, high crushing ration, and big production capacity.

Different types of HXJQ tracked crusher machine for sale have different prices, which are determined by crusher machines' production capacity, yield, energy-saving, etc. Feel free to contact us, HXJQ engineers will design a special production line according to your demands.

Need Some Help?

Our customer service team is here to help you 24/7. We can ship you parts, send field service technicians to your site and answer any questions you have. Whatever you need, we are here for you.

Contact us