HXJQ cone crusher machine has the characteristics of large crushing ratio, high efficiency, low energy consumption, and uniform product size. It is suitable for medium and fine crushing of various ores and rocks with high and medium hardness. The cone crusher machine is widely used in mining, smelting, building materials, roads, railways, water conservancy, and chemical industries.

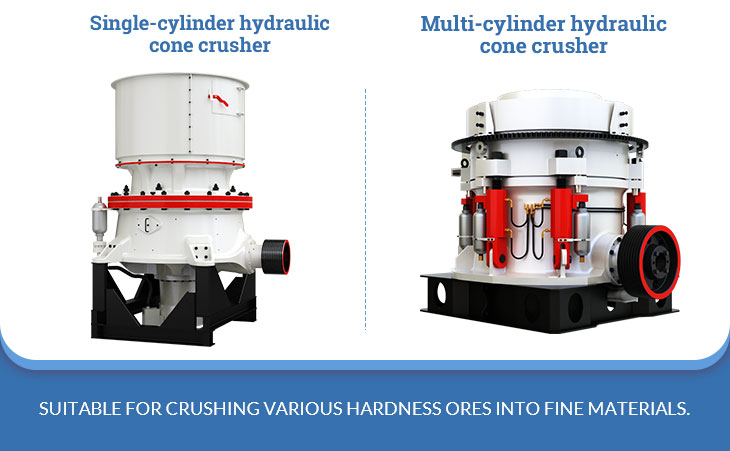

Choosing a hydraulic crushing machine that is suitable for the customer’s crushing needs can increase the efficiency of the crushing, generate higher economic benefits, and bring more value to the customer. Therefore, the selection of suitable crushing equipment has become a matter of deliberation of units or enterprises with crushing demand. So, what is the difference between the appearance and performance of a single-cylinder cone crusher and multi-cylinder cone crusher?

HXJQ single-cylinder hydraulic cone crushers and multi-cylinder hydraulic cone crushers have their advantages respectively

The differences of single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher

- Component configuration

Single-cylinder: upper frame assembly: upper frame, rolling wall, mat, upper bodyguard; lower frame assembly: lower frame, lower frame guard, lower frame inner liner, eccentric bushing, sealing bucket; moving cone assembly: main shaft, moving cone body, rolling wall; drive shaft assembly: sheave, driveshaft, bearing, driveshaft frame, small bevel gear; eccentric sleeve Into weight ring, eccentric sleeve, large bevel gear, spindle bushing; hydraulic cylinder assembly: medium friction disc, lower friction disc, hydraulic cylinder block, cylinder liner, cylinder bottom, displacement sensor. Multi-cylinder: lower frame: frame, main shaft, guide pin; eccentric sleeve: eccentric sleeve, balance ring, large bevel gear; transmission: driveshaft, bevel gear, bushing; support sleeve: support sleeve, lock cylinder, lock nut; adjustment ring: adjustment ring, rolling wall; moving cone: body, broken wall, hammerhead, spherical tile.

- Discharge port

Single-cylinder: When the single-cylinder cone works normally, the oil pump is used to fill or drain the spindle cylinder. In this way, the spindle can float up and down (the spindle moves up or down) to adjust the size of the discharge port. This adjustment may cause the discharge opening to be difficult to lock when performing hard rock fracture. Multi-cylinder: The discharge port adjusting device of the multi-cylinder hydraulic cone crusher adjusts the adjusting cap by a hydraulic pusher or a hydraulic motor, and drives the adjusting ring to rotate in the support sleeve (the fixed-cone spiral rotates up and down) to achieve the adjustment function. The advantage of this adjustment is that the discharge opening can be easily locked during the crushing process.

- Iron protection

Single-cylinder: When the single-cylinder cone crusher passes the iron, the hydraulic oil will be injected into the accumulator. When a certain amount of hydraulic oil is injected into the accumulator, the main shaft will fall and the iron will pass smoothly. After the iron is passed, the accumulator will be hydraulic oil. Press back and turn back to the normal operation. The single-cylinder cone crusher is also operating with a hydraulic pump to clean the chamber. Multi-cylinder: In the operation process of a multi-cylinder cone crusher, when there is foreign matter entering the crushing chamber or causing excessive loading of the crushing equipment for some reason, the hydraulic safety system will automatically adjust to increase the size of the discharge opening to discharge the foreign matter.

When the foreign matter is stuck in the discharge port of the crushing device, the clearing system should be used to enlarge the size of the discharge opening so that the foreign matter can be smoothly discharged from the crushing chamber. Under the action of the hydraulic system, the discharge port will automatically reset after the foreign matter is discharged so that the machine can resume normal operation.

Working principle of multi-cylinder hydraulic cone crusher

- Lubrication system

Single-cylinder: The single-cylinder cone crusher lubrication system fills the two inlet ports, one way from the lower end of the main shaft, lubricating the spherical bearings, spherical tiles, frame bushings, and spindle bushings to lubricate the bevel gears. The other way enters from the end of the drive shaft, lubricating the drive shaft bushing, and the last two oils are discharged from the same oil outlet. Multi-cylinder: The lubrication system of the multi-cylinder cone crusher enters the crusher machine from the oil hole in the lower part of the machine. After reaching the middle of the main shaft, it is divided into three branches: the inner and outer surfaces of the eccentric sleeve, the oil hole from the middle of the main shaft to the ball bearing, and the bevel gear are lubricated through the tunnel.

The other one is filled with oil from the hole in the transmission shaft frame to lubricate the transmission bearing. The oil returns through the oil return hole in the lower part of the small bevel gear and the oil return hole on the dust cover.

- Component parts providing crushing force

Single-cylinder: The single-cylinder hydraulic cone crusher is similar to the spring cone crusher. In the crushing process, the main shaft and the moving cone are combined together, and at the same time, it is carried by the bowl-shaped tile. The main shaft and the moving cone are equivalent to the base support, and the eccentric sleeve drives the main shaft to provide the crushing force. Multi-cylinder: The main shaft of multi-cylinder hydraulic cone crusher tends to be short and thick, and its diameter can be designed very large. It stands directly on the frame (not in the eccentric sleeve). The multi-cylinder hydraulic cone crusher is directly supported by the frame, providing high bearing capacity. The mechanical structure differences between the single-cylinder cone crusher and multi-cylinder cone crusher determine that the force of the frame is different when the two crusher machine crushing ore. The former frame is subjected to tensile stress, and the latter frame is subjected to weak tensile stress, so the multi-cylinder cone crusher is superior in the construction of the frame.

- Feeding method

Generally speaking, the single-cylinder cone crusher and multi-cylinder cone crusher can be fully fed. The high bearing capacity of the multi-cylinder crusher makes it possible to achieve full feeding, and the lamination principle can be used to allow the stone to be carried in the crushing chamber. At the same time, the grain size will be very good because the crushing process has its own shaping effect.

HXJQ single-cylinder hydraulic cone crusher working principle

- Crushing effect

The multi-cylinder cone crusher has a high content of fine particles, which will achieve a finer crushing effect, and a good lamination crushing effect. The single-cylinder hydraulic cone crusher has a better crushing effect and a large passing capacity. In the usual construction process, the multi-cylinder cone crusher and the single-cylinder cone crusher are generally combined.

- Production capacity

When crushing soft ore and weathered ore, the advantage of large single-cylinder hydraulic cone crusher is more outstanding, and when crushing medium-hard and high hard ore, the performance of multi-cylinder hydraulic cone crusher will be more outstanding.

For the fine crushing of medium and hard ore, under the same specifications, multi-cylinder cone can produce more qualified products. Generally speaking, the higher the rock hardness, the greater the difference between single-cylinder and multi-cylinder operation.

- The maintenance of the two types of cone crusher

Single-cylinder: The structure of the single-cylinder cone tends to be simple and reliable: a hydraulic cylinder has a simple and compact structure, low failure rate and low production cost (the simpler the mechanical system structure, the lower the failure rate, the higher the reliability and the more stable the operation).

Production feedback from our customer

Multi-cylinder: The top or side of multi-cylinder hydraulic cone crusher can be disassembled for quick and easy maintenance: all parts can be disassembled and maintained from the top or side, and the moving cone and top cone can be easily disassembled without disassembling the frame and fastening bolts. In this way, ordinary replacement is more convenient.

Indonesia customer has sent their production spot to our engineer

A conclusion for the performance of single-cylinder cone crusher and multi-cylinder cone crusher

Single-cylinder and multi-cylinder hydraulic cone crushers all belong to the crusher machine with high-performance, high efficiency, and high production capacity. They have many advantages in structure, product performance, maintenance and purchase price respectively. Compared to single-cylinder cone crusher, multi-cylinder hydraulic cone crusher will be more advantageous in crushing medium-hard materials, while the single-cylinder cone crusher has advantages in crushing soft rock and ore. Generally speaking, the price of multi-cylinder hydraulic cone crusher will be higher than the single one. In the actual production process, these two types of cone crushers should be chose according to the customer’s practical demand.