Impact crusher can crush aggregates with excellent granularity because of flexible and variable adjustment methods, making the diameter of final aggregates that can be produced reach 0-5mm, 5-10mm, 10-15mm.In addition, people are all inclined to purchasing an impact rock crusher because it can reduce various aggregates to beautiful particle size and little needle content.

What is the ideal aggregate?

As the most important material in concrete use, aggregate is used for concrete framework building. Aggregate can also provide good stability and durability for buildings, can play a role in reducing shrinkage, inhibiting crack growth, transferring force, reducing hydration heat, and providing abrasion resistance.

| Aggregate | classification | details |

| Aggregate resources | Natural aggregate | Sand, pebble chips≤80-3000t / h |

| Artificial aggregate |

1. Hot processed aggregate (expansion rock, vermiculite) 2.Industrial by-products (slag, iron powder) |

|

| recycled aggregate | Concrete slag, sticky bricks | |

| Aggregate diameter(mm) | coarse aggregate(block-type) | >4.75 pebbles, gravel |

| Fine aggregate (sand-type) | <4.75 river sand, hilly sand | |

| Aggregate density(kg/m3) | General aggregate | 2500-2700 |

| Lightweight aggregate | 0-1000Ceramsite, calcined shale | |

| Heavy aggregate | 3500-4000(Iron ore, barite) |

Aggregate is a very important raw material in construction, so what is the ideal aggregate? The ideal aggregate generally has the following requirements:

1) It has sufficient strength and sturdiness to ensure the role of skeleton force transmission.

2) Contains few impurities and must not affect the components of cement hardening and durability of later-stage concrete;

3) It has a good particle gradation so that the stacking porosity is small compared with the surface to reduce the amount of cement slurry;

Ordinary aggregates are not processed or are unsatisfactory because the particle size is uneven, and there are many impurity powders. Therefore, the market price of the ordinary is very low and it is difficult to obtain profits from them. The high-quality aggregate is processed by a rock crusher, which has a uniform particle size, a low powder passing rate, and an excellent grain type. The market value in different countries is very high, so manufacturers can obtain high profits. Therefore, people prefer to invest in high-quality aggregate.

| Country | Normal aggregate | Price (Metric Tons) | High-quality aggregate | Price (Metric Tons) |

| Vietnam | Gravel | $7.50-$8.00 | Gravel | $30-$60 |

| Manlomba | Granite chippings | $5-$10 | Granite chippings | $40-$50 |

| Arab | Limestone | $1-$5 | Limestone | $60-$99 |

Three Performance Advantages of the Impact Crusher

Why can the impact crusher produce ideal aggregates? First, the aggregate produced by the impact crusher has excellent grain shape, mostly cubes, which is extremely beneficial to the increase of the compressive strength and elastic modulus of the concrete, so the aggregate produced by the impact rock crusher has sufficient strength.

Meanwhile, the final aggregate with needle content reduces the viscosity of the concrete mixture and enhances its fluidity and durability. Secondly, it is easy to adjust the impact rock crusher to achieve good particle gradation. In addition, it can handle materials with different characteristics to meet different customer needs.

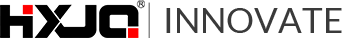

comparison between ordinary aggregate and high-quality aggregate

The following is a detailed performance description of the impact crushers by comparison of impact crushers and traditional crushers:

Crushing Method

As an impact crushing machine adopts an impact crushing method, the aggregate has been crushed by 2-3 crushing cavities, and multiple surfaces have been crushed by hitting impact plate. What’s more, the material is struck along the texture of the stone, so the product shape is almost all cubes.

Even if crushing produces andesite with many needles, the needle content of the finished product is less than 12%. Flaky stones are not good for the strength of concrete, and it is not easy to form a solid skeleton. Cubes and spheres of stones have little effect on the fluidity of concrete and can ensure the strength of concrete. Therefore, at this point, the impact crusher meets the requirements of the ideal aggregate.

The traditional crusher produces a large amount of finished products in the shape of needles with uneven granularity, more powder, and low yield. In addition, because the particle size is not uniform or does not meet the specifications of the finished product, there will be returning charges and waste. The former needs to be processed twice or more, and the waste will be directly discarded.

ideal aggregate produced by impact rock crusher

Discharge Adjustment Methods

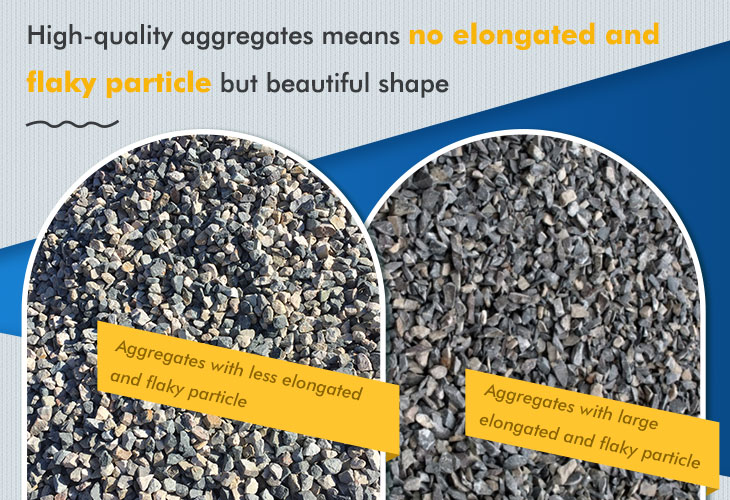

Compared with other crushers, the impact crusher has multiple ways to adjust the particle size of the product, which has obvious advantages in adjusting the particle size of the product.

Regarding the particle size adjustment of the crushing machine, the following methods can be used:

- Adjusting the rotor speed or the diameter of the rotor can easily adjust the particle size of the discharge. Under the same conditions, that step can extend the crushing time, thereby adjusting the particle size of the product, and also increasing the output and improving the material crushing efficiency.

- Change the particle size of the product by adjusting the dispenser. Decreasing the opening of the distributor can increase the material overflow supply, limit the collision motion of the material in the crushing cavity, shorten the residence time of the material particles in the crushing cavity, and improve the throughput of the impact crusher.

- Adjust the gap of the grinding chamber to change the particle size of the finished product. The distance between the impact frame and the hammer can be adjusted hydraulically. The hydraulic type can quickly and easily operate the button or control system to complete the gap adjustment. The closer the distance is, the finer the material is, but it cannot be less than 15mm.

The discharge adjustment method of traditional rock crusher is relatively single, and the discharge particle size can only be adjusted by replacing the sieve at the bottom. The finished product is also relatively single, which is not as rich as the finished product from the impact crusher.

impact rock crusher has three adjustment methods

Handling Materials with Different Characteristics

On the one hand, the impact rock crusher can handle hard materials with compressive strength of no more than 350 MPa, such as limestone, river pebbles, basalt, bluestone and so on. When the impact rock crusher operates, the hammer has large rotational inertia as the rotor rotates. Compared with the hammer crusher, the rotor of the impact crusher has greater kinetic energy, which can crush harder materials with lower energy consumption. In May 2019, Mr. Maderson, a Zimbabwean customer, needed a 1,000-ton “limestone” sand production line. Knowing his production conditions and high-quality requirements for aggregates, we made the following plan for him:

| Equipment | Model | Sets |

| Material silo | – | 1 |

| Vibration feeder | ZSW600*180 | 1 |

| Jaw crusher | PE1500*1800 | 1 |

| Impact crusher | PF1820 | 2 |

| Vibrating screen | 3YK3072 | 2 |

| Vibrating screen | 3YK3072 | 2 |

| Conveyer belt | – | 17 |

Feed size: ≤1200mm

Finished product specifications: 0-5, 5-10, 10-20, 20-30, 30-40mm

Investment cost: <6.23 million yuan The main equipment of the limestone sand production line with an output of 1,000 tons per hour: PE1500*1800 jaw crusher (for coarse crushing): feed size: ≤1200mm, the adjustment range of discharge port: 220-350mm, speed of eccentric shaft: 180r / min, motor power: 8P 280-355KW. PF1820 impact crusher (for Medium and fine crushing): feed size ≤ 800mm, motor power:4P 630-710KW. The PF series impact crusher is relatively mature and novel in structure and it is designed and developed in combination with the characteristics of limestone. The equipment has less downtime, high operating efficiency, low energy consumption, large production capacity, and no noise and dust pollution in actual operation, which fully meets the requirements of national environmental protection standards. At the same time, the high chrome hammer is adopted for impact and wear resistance with good grain shape and less stone powder produced. The largest advantages of this limestone production line:

- Excellent grain shape keeps customers very satisfied.

- Besides several operations and monitoring such as setting and controlling the feeding quantity, feeding speed and discharging particle size, basically, no other manual operations are required.

- Itis developing rapidly towards larger scale, automation and integration.

- The required crushing particle size can be adjusted by yourself.

Customer feedback for using our production line

“I am very satisfied with the limestone production line recommended by Hongxing Machinery. This production line has a large output and good finished products, which makes the market value of my product much higher than others and brings me a good return. Thanks very much.”

On the other hand, the impact crusher can process the aggregates with large water content. The feed chute and impact plate of the impact crusher can be equipped with a heating device. When processing aggregates with large water content, it is not necessary to be equipped with a sieve plate at the bottom, and the material can be effectively prevented from sticking only by heating. It not only simplifies the equipment structure but also improves the crushing efficiency.

Three unique advantages Why Hongxing Impact Rock Crusher Can Break High-quality Aggregates

On this basis, the R&D team of Hongxing Machinery has made breakthroughs in the following three aspects after years of continuous testing and improvement of the machine:

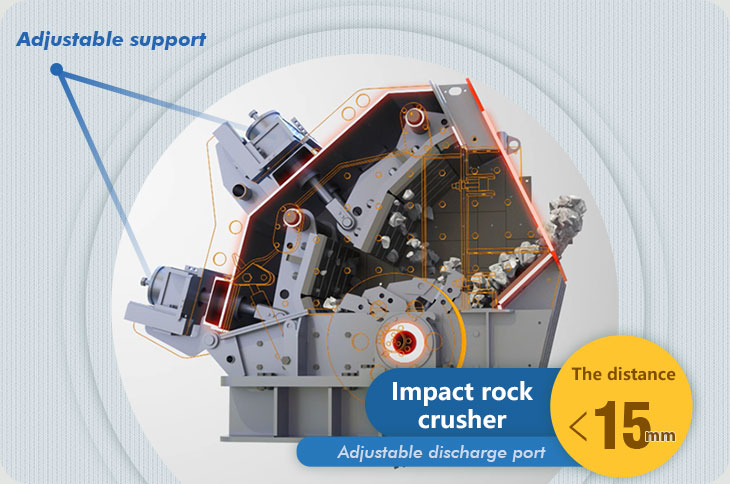

Wear-resistant Parts

The hammer is the core part of the impact rock crusher. However, it is vulnerable to wear due to the constant impact of aggregates. Therefore, the wearability of the hammer determines the service life of the impact crusher. The hammer of Hongxing impact crusher, which is made symmetrically, is characterized by its high exploitation rate (approx. 50%~60%) because it can be turned over for use.

high-quality impact rock crusher hammer

While the wear of wear parts varies greatly due to different physical and chemical properties of different aggregates. Therefore, according to the actual needs, we provide hammers of different materials for various aggregates. The most commonly used material in the crushing field is high manganese steel, which has a history of more than 100 years with the characteristics of good toughness and hardening under the strong impact.

In addition, it’s also found that alloy materials have the advantages of high toughness, low cost, and good wear-resistance, which have been gradually put into practical application. Due to the small reserves, they cannot meet a large number of demands, so their price is relatively higher.

three different types of hammers

What are the characteristics of hammers made of different materials? What materials are these hammers applied to?

| High chromium iron | Medium chromium iron | High Manganese Steel |

| Casting condition ≥46 HRC | Tensile strength(Mpa)≥1080 | Tensile strength Rm/Mpa≥735 |

| Harded condition ≥58 HRC | Yield strength(Mpa)≥930 | Yield strength ReH/Mpa≥390 |

| Softening annealing condition≥41 HRC | Elongation at cross section(%)≥12 | Elongation at cross-section %≥20 |

| Softening annealing condition≥41 HRC | Reduction of crosssection area(%)≥20 | Hardness HB ≤300 |

| Softening annealing condition≥41 HRC | Shock absorption energy(KV2/J)≥24 | Hardness HB ≤300 |

| Asphalt, highly abrasive material | Most steel contaminants, some asphalt |

Concrete, abrasive, concrete, lightweight aggregates, some steel contaminants |

| Smaller feed | Larger feed | Larger feed |

The hammer produced by Hongxing Machinery is made by the heat treatment process for special material, which not only ensures wear-resistance but also guarantees that it will not break. Its service life is 3~5 times that of ordinary material.

Rotor

The rotor is the “heart” of the impact rock crusher, so it is strictly inspected. It plays a vital role in the working process.

- Hongxing Machineryadopts a new heavy-duty rotor structure design, which improves the handling capacity and crushing ratio of the impact crusher; The finite element analysis technology, three-cavity crushing, and large-size bearing design are adopted to reasonably match the rotate speed, which can meet different applications of coarse, medium and fine crushing and aggregates recovery.

- With strong rigidity and large inertia, coupled with the design of keyless connection, the rotor can form the aggregate at one time, which simplifies the crushing process and reduces the repeated useless work, making the overall output higher.

- Our rotor has passed the balancing treatment before leaving the factory, so the user does not need to carry out the balance test again. However, the hammer and rotor should be replaced with the balancing configuration when operating by yourself.

- The rotor has the dual efficiency of hammer crusher and impacts crusher with sufficient crushing, good particle shape, high production efficiency, energy-saving, Short maintenance time and low maintenance difficulty.

higher rotor speed, finer aggregate is

The unique rotor design of Hongxing Machinery not only simplifies the crushing process, ensures high yield and high quality of the impact rock crusher, but also meets the crushing of different aggregates. Therefore, in virtually every way possible, the design of our rotor absolutely serves multiple purposes.

Easy maintenance

Hongxing impact crusher adopts an automatic control system and is equipped with a control panel, which is easy to operate and the staff are able to work without long-time training. Maintenance is more convenient and faster, saving a lot of costs.

- The automatic detection function can ensure the safety and reliability of equipment operation;

- The equipment is also equipped with unique hydraulic cover opening design and multiple safety locking devices to improve safety performance while reducing labor intensity and shortening downtime;

- Improved adjustment device makes operation more convenient, which reduces downtime and maintenance time;

- Only 6hammers are installed on the rotor of the equipment, which can be easily replaced and the replacement time is short; The replacement of the bottom grinding rod also takes only ten minutes;

- The hammer is fixed by the wear-resistant block and embedded into the rotor body, which can be self-centering automatically during operation, enhancing the reliability of the hammer and facilitating installation and replacement;

best impact rock crusher manufactured by HXJQ

In short, due to the unique characteristics of our impact rock crusher, the aggregates produced by us can satisfy people’s common requirements. Three unique designs of Hongxing Machinery make the finished product excellent in granulation, uniform in size and less in impurity in addition to ideal particle size grading standard, which has greatly improved the market value of high-quality aggregates and brought super high profits to manufacturers.