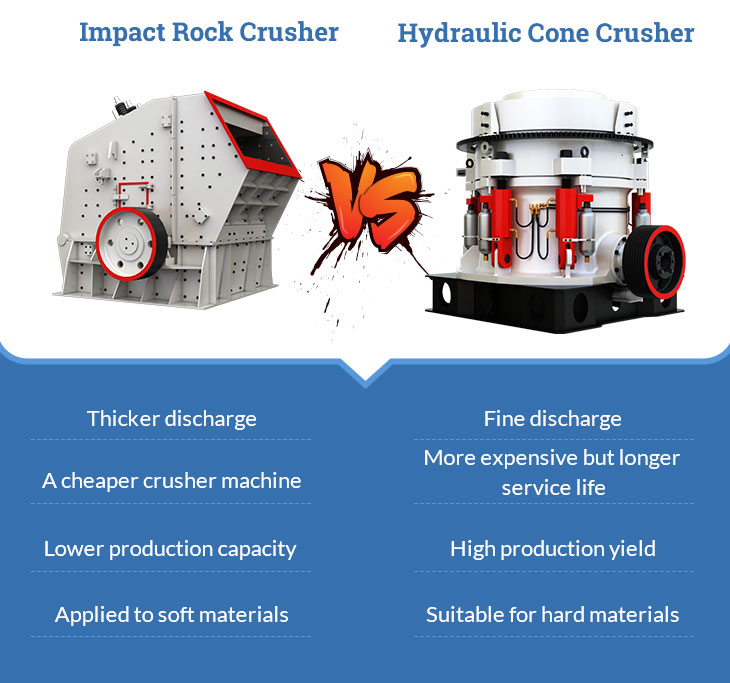

The secondary crushing stage is widely used in building materials, mining, metallurgy, chemical industry, etc. Both hydraulic cone crusher and impact rock crusher machine all belong to the secondary stone crusher, there are still some differences in the usage of two stone crushing plant.

What Are the Main Differences Between the Impact Rock Crusher and Hydraulic Cone Crusher

- Different raw materials application

The impact rock crusher machine and hydraulic cone crusher can both act as secondary stone crusher, but the hardness of the materials tends to be different. In general, the cone stone crushers mainly crush hard materials such as granite, basalt, tuff, river pebble, etc., while the impact rock crusher machine is used to crush materials with low hardness such as limestone and limestone. In a word, the impact rock crusher machine for sale is suitable for crushing medium and soft materials, and the hydraulic cone crusher tends to be suitable for crushing hard materials.

- Different discharge granularity

The hydraulic cone crusher machine: the discharge is fine, and the most finished products present needle-shaped, so the cone crusher machine beneficiation often uses a hydraulic cone crusher machine.

Impact rock crusher: the material is coarser, the finished product has fewer corners, more powder, and better grain shape, which is used more in building materials and construction projects.

In actual production, the granular cube shape of the ore product tends to be particularly strict (ie, the needle-like particles are relatively small), so the impact crusher is often used.

- Different production capacity

Compared with the impact rock crusher machine, the hydraulic cone crushers have the characteristics of low energy consumption, large output, stable production, etc., so the cone crusher machine is often used for large-scale and high-yield production line operations.

- Different input cost

The price of the hydraulic cone crusher machine will be higher than the impact rock crusher, but the service life tends to be longer, avoiding the trouble of frequently replacing parts. In the long run, the cone crusher machine is more cost-effective than the impact rock crusher. It can be understood that the pre-recovery cost of the impact crusher is low, and the post-maintenance cost is high; the pre-cone cost of the cone crusher is high, while the input cost will be lower.

- Different pollution degree

Compared with the impact rock crusher machine, the cone stone crusher will be less polluted and the noise is lower, which is more in line with the environmental protection concept advocated. Although the impact rock crusher is relatively large in terms of pollution, the pollution degree is within reasonable control. Therefore, users do not have to worry about the pollution problem.

Several differences between stone crushing plants

Both the two stone crushing plants have their own advantages and disadvantages, and which crushing equipment should be used in actual production is based on the raw materials, grain size, output, and input cost. The performance of the cone crusher machine is mainly reflected in the aspects of the feed size, processing capacity and discharge granularity. At present, the large and medium-sized gravel field is mainly hydraulic cone crusher.

The hydraulic cone crusher is optimized in combination with the speed, stroke and crushing cavity type to achieve inter-granular lamination crushing, which significantly increases the output and greatly improves the shape of the finished product. The hydraulic adjustment discharge opening and overload protection device greatly improve the operation efficiency, making maintenance and shorter downtime.

In addition, the CCM series full hydraulic cone crusher discharge port is adjusted by hydraulic motor. In addition, when the improved bumper and accumulator of the cone crusher machine suddenly increase the iron load, the hydraulic oil of the bumper can instantaneously flow back to the accumulator, and the piston rod can be quickly lifted to better protect the crusher machine, reducing the damage of the impact load to the machine.

However, if it is a small stone production line, consider counterattacking. During the counter-attack work, the ore obtained huge kinetic energy from the impact process, and was thrown at the high-speed to the first-level counter-attack. Due to the counterattack effect of the counter-attack plate, the ore was again subjected to the broken piece, and the ore that was rebounded by the counter-attack plate was again subjected to the impact of the hammerhead. And the impact of the hammerhead continues to repeat the above-mentioned crushing process.

After that, the broken ore is again thrown to the second-stage counterattack plate at a high speed. In this way, through the multiple successive impacts of the counter-attack plate and the successive collision, the ore can be finally crushed. When its particle size is smaller than the gap between the hammerhead, the raw material will be shaped into a qualified finish product.

A customer from Africa is very satisfied with the impact rock crusher

Customer Case

Mark is a customer from Tanzania. After clearly understanding Mr. Mark’s requirements and on-site inspections, China Hongxing manufacturer designed a special production line: the fixed jaw crusher is equipped as a coarse crushing machine and the impact rock crusher machine is the secondary crushing equipment. When the production program is completed, the quotation of the entire production line equipment will be sent to the customer in a short time. And our customer was very satisfied after seeing it. What are the advantages of the production program?

- Labor-saving and worry-free

From the selection of the production line to the configuration of the crushing equipment, the whole process is undertaken by our engineer, and the user investment and project construction are quite clear. The user just waits until the start of the construction period, so the whole process is labor-saving and worry-free.

- Mature technology, reliable crushing equipment

The production line plan is designed according to customers’ local conditions, and the layout of the whole production line is compact, reasonable and smooth, and the quality of all crushing equipment is quite reliable. The annual failure rate can be shortened by 40%. The whole production line equipment is at a high level, ensuring the production line efficient and stable operation for a long time.

- Green protection, energy-saving

The environmental protection design level of the production line is quite high, which is in line with the domestic environmental assessment and safety. The noise and dust pollution of the entire production line has been reasonably controlled, which will not affect the surrounding environment, improve the economic benefits of the enterprise and social benefits.

Mark is very satisfied with this production line

Feedback from this customer:

- The reputation of the manufacturer is good in our country. One of my friends also selected the HXJQ stone crushing plant. I have visited the factory, and the production line designed by their engineers can meet environmental protection standards.

- he manufacturer’s service attitude is good, the design plan is more reasonable, and will be solid and practical for our customers, only design the most suitable production line for users.

- Compared with the equipment quality, program design, price investment, of various manufacturers, Hongxing manufacturer tends to be more cost-effective.

What’s the price for the two rock crushers for sale?

Hongxing machinery crusher machine production plant

The price is based on the modes and yield. Hongxing Machinery cone crusher machine can be divided into the single-cylinder hydraulic cone crusher, compound cone crusher, multi-cylinder hydraulic cone crusher, and full hydraulic cone crusher. And the impact rock crusher can be divided into CI series impact rock crusher and HX series impact crusher. Which mode should be selected depends on the raw materials and production spot. So feel free to contact us, we will design a special production line for you!