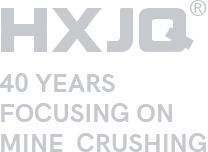

Different structural designs of the two crushing equipment

The structural design of fixed jaw crusher is relatively simple, mainly consisting of automatic lubrication system, hydraulic friction clutch, hydraulic connecting road, and thrust plate (as safety devices), overload protection device, hydraulic adjusting device, inclined iron adjusting device, pad adjusting device, transmission mechanism, working mechanism, rack. While the structural design of impact rock crusher mainly consists of machine shelves, rotors, transmission mechanism, counterattack plate, hammerhead, etc.

Structural differences between the fixed jaw crusher and impact rock crusher.

Applying to different crushing stages

The fixed jaw crusher (also called concrete crusher)is generally used in primary crushing, during which large materials would be crushed to be suitable for secondary crushing equipment like hydraulic cone crusher machine, impact rock crusher, roller crusher. Since feeding size of secondary crusher is generally small, a large-sized stone must be resized by fixed jaw crusher at first. The impact rock crusher for sale is generally used in secondary or tertiary crushing. It is suitable to crush materials like granite, marble, etc. Materials with high hardness are not suitable for impact crusher since they will damage the easy-wearing parts during the crushing process.

Impact crusher, whose finished product is in cubic shape without tension and crack, can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with feeding size less than 500mm and compressive strength not more than 350MPa. What’s more, the discharging size can be adjusted and the crushing specification is various.

The feeding size of impact rock crusher should be less than 500mm

Fixed jaw crusher machine is mainly used in secondary crushing of a variety of ores and bulk materials with compression strength no more than 320Mpa. The crushing process can be divided into coarse and fine crushing. The series of fixed jaw crusher is very complete and its feeding size is in the scope of 125mm-750mm. In a word, it is the best fixed jaw crushers machine for primary crushing.

The feeding size of fixed jaw crusher ranges from 120-750mm

Different working principles of the impact rock crusher and fixed jaw crusher

During the working process of impact rock crusher, rotors are driven by the motor to rotate at a high speed. After raw materials get into the plate hammer working area, they are greatly hit and crushed by the plate hammer on rotors, then crushed by impacting device for secondary crushing, at last, crushed by impact liner for tertiary crushing. This process is repeated again and again until the material being reduced to the required size.

When it comes to the fixed jaw crusher, the motor drives the belt and the pulley, acting on the eccentric shaft to move the mobile jaw up and down. When the mobile jaw rises, the angle between the toggle and the mobile jaw becomes larger, hence pushing the mobile jaw plate close to the fixed jaw plate for the crushing purpose. When the movable jaw goes down, the angle between toggle and the mobile jaw becomes smaller. Being driven by the pull rod and spring, the mobile jaw plate leaves the fixed jaw plate to discharge crushed material from the crushing cavity. With the continuous rotation of the motor, the mobile jaw does the periodic movement to implement mass production.

Working principle of fixed jaw crusher and impact rock crusher

Different performances of the HXJQ Machinery crushing machines

The impact rock crusher has the advantages of large feed mouth, the high crushing cavity and great power to process high hardness material with large block size. More, stone powders are rare to see during the process.

The interval between the impact plate and plate hammer can be easily adjusted, which can effectively control the discharging size and ensure good particle shape. Besides, it is also characterized by compact structure, strong machine rigidity, large inertia of rotor movement, high chrome plate hammer(being equipped), strong wear and impact resistance, etc. People also can benefit from its convenient maintenance, economical and reliable coupled with versatile functions, high productivity, low wear of parts and high comprehensive benefits.

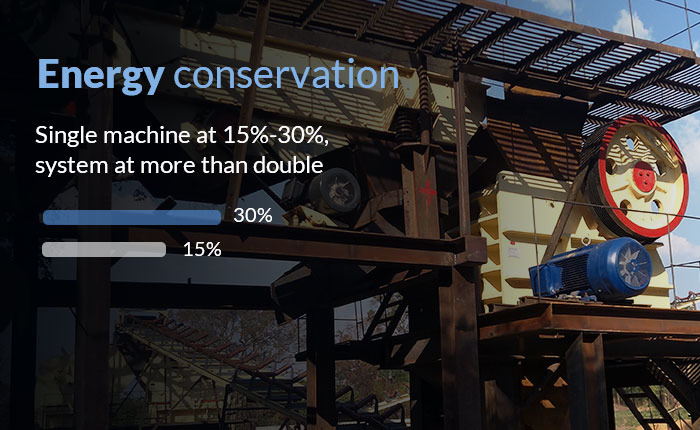

Performance of fixed jaw crusher: deep crushing cavity without dead zone improves the feeding capability and productivity. Apart from the high crushing ratio and uniform product granularity, an adjustment device of gasket-type discharge opening is reliable and convenient. Because of the wide adjustment range, the flexibility of the jaw crusher machine has been greatly improved. Another attractive feature is energy conservation (single machine at 15%-30%, system at more than double). The wide discharging scope can meet the requirements of different customers. More, the jaw crushing machine enjoys the features of lower noise and less dust.

Fixed jaw crusher machine enjoys the feature of energy conservation

In general, fixed jaw crushers used in primary crushing mainly process the materials with large size. While impact stone crushers in secondary crushing usually crush middle-sized materials. They both work on the squeezing power to crush stone materials. But, they are different in crushing degree related to the internal structure and working principle.

The impact crusher adopts rotary swing while Jaw crusher has two ways for swing, one is simple pendulum and the other is a complex pendulum. In short, the former adopts a rotational swing to finish crushing work, whose trajectory is circular while the latter utilizes reciprocating swing, whose extrusion motion is a straight line.

Compared with the Hongxing Machinery fixed jaw crushers, the working process of the impact rock crusher is continuous, and the force on the material in the cavity is the combination of bending force, shear force, and friction. Based on that, raw materials are easy to be crushed. Moreover, impact crushing machine enjoys the features of high working capacity and low power consumption.

Different sides of rock crushers on environmental protection

Energy-saving and environmental protection are the hottest topics of the new century. With human beings pay more and more attention to the environment, the proposal and advocacy for energy conservation and environmental protection are carefully planned. And so far, obvious outcomes have been made. Especially in the mining industry, the update of crushing machines gets rid of dust pollution, creating a green and fresh environment.

Even if the two crushing machines are both eco-friendly, they have different sides. The Hongxing Machinery impact rock crusher for sale has advantages in low energy consumption while the impact rock crusher has a breakthrough in terms of reducing noise. The energy consumption of impact rock crusher Low energy consumption is a powerful manifestation of energy-saving and environmental protection. The low energy consumption of impact crusher is mainly because the motor performance is fantastic. It is equipped with international quality components whose parameters can meet the actual needs of users. In other words, the low-power motor can greatly reduce energy consumption and improve the strength of environmental protection.

HXJQ impact rock crusher machine for sale has the advantages of environmental protection, aiming to create a green environment

Fixed Jaw crusher: noise reduction Noise is also a factor affecting energy conservation and environmental protection. According to the environmental protection survey report of 2015, noise not only threatens the living environment of human beings all the time but also harms the physical and mental health of human beings. Therefore, the radical treatment of noise is urgent to be solved.

The emergence of noise cancellation circuit installed on the fixed jaw crusher immediately attracts more attention from miners, because it not only fundamentally solves the noise problem, but also improves the reliability on energy conservation and environmental protection. The noise cancellation circuit is very flexible and it can be set on different parts of a jaw crusher according to the noise degree.

4 Differences between fixed jaw crusher and impact rock crusher in the production line

1. Different positions in the production line As we all know, in the stone crushing plant, sand making plant and ore beneficiation plant, the fixed jaw crusher is commonly used for coarse crushing (except the PEX jaw crusher, which can be used for secondary or tertiary crushing), impact rock crusher is commonly used as secondary or tertiary crushing equipment for medium crushing or fine crushing.

2. Different capacity In general, the capacity of the fixed jaw crusher is greater than that of the impact rock crusher. The former output can reach to 600-800t/h (depending on the manufacturer and product model) while the latter output is about 260-450t/h. 3. Different final-sized products Fixed jaw crusher as a coarse crushing machine has larger discharge size generally in 300-350mm (depending on the manufacturer and product model). Impact rock crusher as a medium or fine crushing machine obviously has a smaller larger discharge size.

It should be noted that, due to the different properties of materials, there will be errors in the output precision of the equipment. 4. Different product shape The granule shape of the fixed jaw crusher is not ideal because of too much needle-sheet content and the grain shape is also better than the cone crusher. Therefore, in the actual production, for further material shaping, the impact rock crusher is usually matched with the fixed jaw crusher.

The finished product tends to be different by fixed jaw crusher and impact rock crusher respectively

The prices of the two kinds of rock crusher machine for sale

When customers buying a fixed rock crusher machine or impact rock crusher, what concerns them most maybe the machines’ price. And the price relies on the types of the crusher machine. Besides, high-yield crusher machine for sale will lead to a higher price. Therefore, if you want to know about the prices of fixed jaw crusher and impact rock crusher for sale, feel free to contact us, our engineers will design a specialized production line for you according to your requirement! In a word, HXJQ impact rock crushers and fixed jaw crushers are the crushing equipment full of high efficiency, which is produced by China Hongxing Machinery, and the crusher equipment also has passed the ISO9001 quality system of certification and is one of the 10 impact rock crusher manufacturers in China. Welcome to buy impact rock crushers, fixed jaw crushers, or acquire the latest quote of stone crushers price, we are waiting for you all the time!