Customer Case

A customer called Taylor wanted a roller crusher to handle limestone cap. He consulted our customer service the price of the crusher machine. Taylor said he would use roller crusher to apply to rotary kiln industry. The yield he wanted is 5-10 tons per day. And he has shown his concern about the quality of our roller crusher and the after-sale service in Hongxing Machinery. When it comes to the quality of the Hongxing Machinery roller crusher for sale, it has passed ISO9001, CE, and GOST international quality system certification.

Besides, our technician will install the roll crusher by in person. There is a mobile device equipped in every double roller, the customer can contact our engineers if there are any problems with the roller crusher. Therefore, you don’t have to worry about the quality of the roller crusher for sale. We will do our best to satisfy all customers. After a detailed introduction of the quality and after-sale service in Hongxing Machinery, Taylor came to China Hongxing Machinery to check the roll crusher for sale. And he was satisfied with our crusher machine.

An introduction to roller crushers for sale

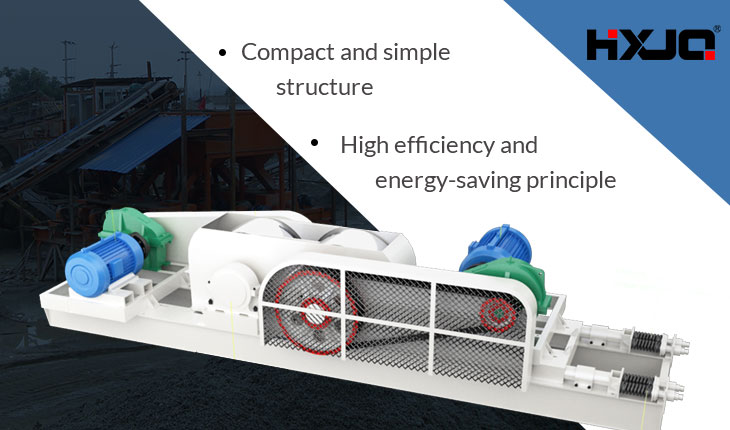

Roller crusher, a kind of mining machine, also known as a double roller crusher, which is mainly used to break the ore.

The roller crusher machine has the advantages of small volume, large crushing ratio, low noise, simple structure, and convenient maintenance. The materials crushed by roller crusher has a uniform particle size, which meets the requirements of most consumers. The roller crusher machine applies to coal, metallurgy, mining, chemical, building materials, and other industries, and this crusher machine tends to be more suitable for the crushing of large coal mine or raw coal (including vermiculite).

The roller crushers’ working principle

The roller crusher has a large crushing capacity, and the motor and the reducer are connected by a limited-range fluid coupling to prevent power overload and the sensor’s overload protection.

The pitch of the toothed rolls is hydraulically adjusted, and the toothed roller bearings are concentrated and lubricated. Besides, the tooth shape is optimized, so the efficiency is high while the consumption is low. Most importantly, and the granulation after crushing is uniform.

A roller crusher that crushes materials using two counter-rotating rollers. This crusher machine consists of an electric motor, a bracket, a fixed roller, a movable roller, and a safety spring. The roller surface is mostly smooth, and the bearing of the movable roller can be moved along the frame, which is supported by a strong safety spring.

When a particularly hard object falls in, the bearing can be removed and the object can spit out. Before the normal operation, the gap between the two rollers should be adjusted to ensure the crushing ratio.

The roll crusher working principle

Roller crushers’ advantages

- Equipped with PDG-II in the grinding system, the production capacity of the roller crushers can be fully utilized, generally increasing 30%-40%, and the total energy consumption can be reduced by 20%-30%.

- Compared to the grinding system with identical production capacity, the roller crusher equipped PDG-II system can save the capitalized cost because of its compact structure, lightweight, and small volume. Besides, the roll crushers for sale are more easily to maintain because they occupy smaller space.

- The inside of the crusher machine is equipped with a dustproof board, which has good sealing performance, avoiding the splashing of fine materials after crushing. Besides, there is less dust and low working noise in the process of operation, and the working environment will be greatly improved.

- The abrasive roller body of roller crusher in Hongxing Machinery is redesigned and optimized. Therefore, the roll crusher does not need to change the roller body. While the old double roller needs to be dismantled and replaced after one year of use. In this sense, the roller crusher in Hongxing Machinery adopts advanced technology to meet customers’ needs.

- The roller crushers for sale in Hongxing Machinery is equipped with a replaceable wear-resistant lining plate, adopting domestic advanced wear-resistant materials, which have the advantages of long service life and convenient for maintenance. When the wear is serious, the cover can be replaced. In conclusion, the maintenance volume is small and the cost is low, which is unmatched by any other domestic types of crusher machines.

- There is a safety device equipped in Hongxing Machinery roller crushers. When an accidental metal iron piece enters the crushing chamber, the protective device will play a role in driving the crusher machine to normal operation.

- The roller crushers’ structure is simple and reasonable. The crusher machines’ running cost is low, the operation is stable, and the crushing efficiency is high. Besides, the discharge granularity can be adjustable. The roller gap of the roller body of the roller crusher can be arbitrarily adjusted between 1mm and 20mm.

- After the roll gap is adjusted according to the requirements of the crushing particle size, the crushing particle size can be reliably controlled, and all of them are discharged from the bottom of the crushing chamber at ideal particle size.

The Hongxing Machinery roller crusher has many advantages to meet customers requirements

The roller crushers’ maintenance

- It must be started without load. Before starting up, all components of roll crushers should be checked carefully. It must not be started after feeding. When the machine is shut down, the material must be completely discharged, and no residual materials can be stored in the hopper to prevent the machine from being damaged due to misoperation during the next startup.

- To ensure the long-term good condition of the roller crusher, it is necessary to refuel all parts frequently. The bearing pad is equipped with copper tiles, which are used after each shift. The bearings in the 200×125 and 200×150 bearing housings are filled with calcium grease every three months, and the chain is refueled once a week. The sprocket shaft adds calcium base grease every fifteen days. The chain is thoroughly cleaned once a month with diesel.

- Frequently check the usage situation of the roller crusher, the double roller requires a smooth appearance. If the pits and large scratches phenomenon happens, the new pair of rollers should be replaced. When adjusting the gap of the double roller, it should tighten the adjusting handwheel firstly, then loosen the handwheel and adjust the distance of the handwheel by 3 mm.

- Lock the nut when adjusting to a suitable clearance to prevent causing partial wear of the bearing pads. When feeding the materials, the materials should be checked carefully to prevent super-hard materials and iron from entering the machine.

- Always check the V-belt and sprocket chain used in the roller crusher. If the damage level reaches 30%, it must be replaced with new ones. Besides, roller crusher should be thoroughly inspected once a year.

- It is necessary to strengthen the iron removal work for the roll crusher. If the non-crushed material (such as a bit) falls into the double rollers, the crusher will be damaged, resulting in the phenomenon of halt. Therefore, a de-ironing device should be installed in front of the roll crusher.

- The viscous material is easy to block the crushing space. It should be stopped when handling the blockage failure, and the antimony ore should not be carried out during operation. After the roller crusher is operated for a long time, the wear of the roller crusher surface will be large, and the product size will be too fine. At this time, it is necessary to pay attention to adjusting the discharge port or overhauling the equipment.

Some preparations before roller crushers starting up

First of all, before starting up the roller crusher machine, it is necessary to check whether the components are complete and intact, whether the safety devices, lighting, and signals are in good condition.

Besides, check whether the amount of oil is sufficient and the oil quality is clean. The most important thing is to check whether there is any foreign matter in the roller crusher, whether the device is flexible and reliable, whether the load pin is intact, whether the dustproof or spray device works.

This picture is from our customer, Taylor. He says the roll crusher has good performance and stable operation, and the yield also meets his requirement.

The roller crushers’ matters needing attention in the process of operation

- The roller crushers must be started without load.

- After receiving the power-up signal, the feed charge door should be open first, then the crusher machine ought to be started right behind. The roller crusher will be in normal operation after the current drops to the normal value.

- Always check whether the motor and bearing temperature is normal, whether the current indication is within the required range, whether the operation sound of the crusher machine is abnormal. And if accidents and hidden dangers are found, the crusher machine should be stopped immediately, and send an emergency stop signal to the dispatch control room and related posts.

- It is strictly forbidden to open the observation hole during production to prevent the materials from flying out and hurting people.

- Check whether the particle size meets the requirements. If there is serious super-granulation phenomenon, it should be reported in time.

The roller crushers’ self-protection when fortuitous events happen

To prevent unpredictable large pieces or objects from affecting normal operations, when foreign matter enters the crushing zone, the roller breakage is required to be automatically processed, so the crushing pressure must be limited. The roller crusher for sale is driven by the motor, and the automatic matter processing function can be realized by limiting the motor current.

If the foreign matter enters the area between the two roller shafts, once the current of the driving roller shaft exceeds the set current, the rotation direction of the corresponding roller shaft automatically reverses in a short time to reverse the foreign matter.

Subsequently, the roller automatically switches back to the previous direction of rotation, and this procedure is called reverse cycle. If the reversal reaches 5 times within five minutes, it is considered that there is an unbreakable object such as iron block entering the roller brake, and the roller breaks the shutdown alarm. Therefore, the roller crusher machine in Hongxing Machinery can automatically adjust the potential dangers, which dispelled customers’ concerns.

The price of roller crusher for sale

Many customers consulted the price of roller crushers for sale. Different model has a different price. If you want high-yield roller crusher, the price will be higher than the crusher machines with low yield. Besides, our engineer will design a specialized production line for customers. More importantly, engineers in Hongxing Machinery will install the crusher machines by themselves.

In addition to the roller crusher, there are also other types of crusher machine, namely fixed jaw crusher, portable rock crusher, hammer crusher, impact rock crusher, etc. If you are interested in the crusher machine in Hongxing machinery, please contact us, we will give you the most reasonable price.