The green development of the aggregate of sand and gravel has been the focus of the mining industry(like Hongxing Machinery). Studies have shown that sand aggregate has become the second-largest consumption of humans, which ranks only second to freshwater. Currently, like high-speed railways, highways, and tall buildings. Almost every construction of the building does require a lot of sand and gravel aggregates. So what is the aggregate? Follow us and read below!

What is the aggregate? Or what does aggregate mean?

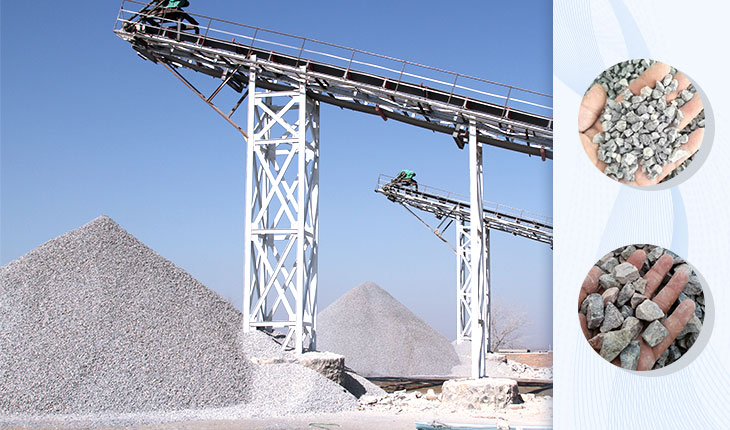

The aggregate can be crushed into fine materials by HXJQ crusher machine

As is known, the aggregate plays an essential role in filling and erecting on the concrete, and it takes on the shape of loose granular. It can also make a contribution to improving the durability and stability of the concrete.

Regarding to the source, the aggregate can be divided into natural, artificial and regenerated ones. According to the particle size, it can be separated into coarse aggregate and fine aggregate.

What’s more, according to the density, it is grouped into ordinary aggregate and light aggregate. Fine aggregates with a particle size between 0.15 and 4.75 mm are commonly known as sand, and coarse aggregates with a particle size between 4.75 and 9.0 mm are commonly known as a stone. Due to the gradual depletion of natural sand and stone aggregates, while the artificial sand and stone markets become hotter. Mechanical equipment can process various materials such as the slag( rock, waste, etc.) into the required particle size, for example, The PEX jaw crusher of Hongxing Machinery can crush various aggregates with different hardness.

What is the production process of aggregate?

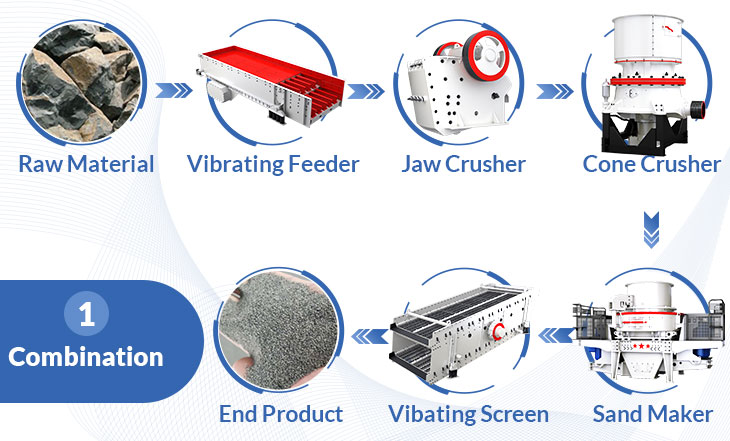

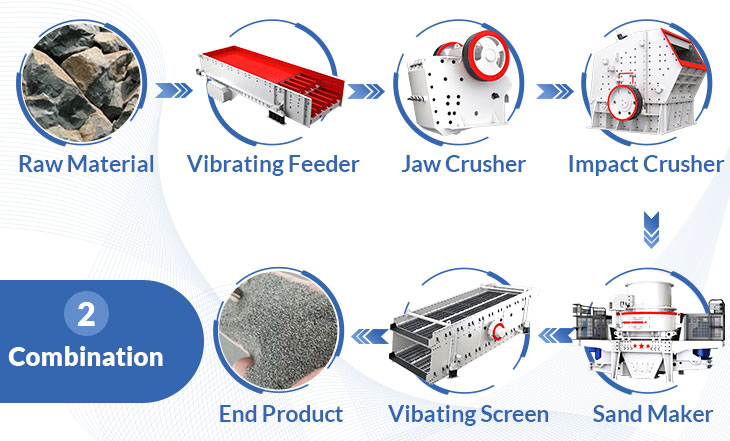

The choice of the aggregate production line is an important part of modern aggregate production. The complete production line consists of four major systems: the feeding system, the crushing and sand making system, the screening system, and the sorting system.

The lightweight aggregate produced by this process is a ceramic chemically neutral product that may have a wider range of applications than natural aggregates due to its physical properties. It has the advantage of being lightweight and durable with a bulk density of 550 to 720 kg / m3 (35-45 lb / ft3). It is suitable for concrete manufacturing, including prefabricated road construction and construction applications.

Pretreatment of aggregate in bulk material

At this stage, the bulk material or brittle material in the gravel aggregate ore is pre-crushed by the hammer crusher, and the debris that is not suitable for crushing will be sorted out, and the waste wood, plastic, and other debris are removed to facilitate the next process. The initial magnetic separation is performed to remove the scrap iron in the aggregate.

The crushing process for making sand

Firstly, the raw material will be crushed by a jaw crusher in the first stage, and the vibrating feeder will feed them immediately, and the large-sized gravel aggregate is crushed into a smaller particle size by using the jaw movement. The coarsely broken material is transported by the conveying equipment to the transfer pile. The material can then be finely divided and shaped using a sand making machine, and the aggregate size of the aggregate after the sand making machine is uniform.

The first screening stage

At this stage, a kind of circular vibrating screen manufactured by Hongxing Machinery is used to divide the concrete aggregate fractured coarsely into a block of 0-40 mm and the crushed material of 5 mm or less. The coarse aggregate of 5-40mm can be directly used for the general C15-C20 concrete production. Fine aggregate can be transported to the intermediate stack for the next process.

Secondary crushing and screening stage

During the crushing process, the fine aggregate can be pulverized again by using a ball mill. The secondary screening can divide the crushed aggregate into 5-20mm with high-quality of recycled aggregate, which can be used for C25-C30 concrete production. The third-stage screening can sort out the recycled fine aggregate with high quality in 0.15mm-5mm and fine powder below 0.15 mm.

Recommendation for Environmental Protection About Sand and Stone aggregate equipment

According to the development trend and market demand of the industry, the vu high-quality aggregate optimization system introduced by Hongxing Machinery, the finished sand and stone grain shape is round, the gradation is reasonable, the powder content can be controlled, and the quality is in accordance with the national standard, and the production process is zero silt, zero wastewater, no dust, which fully meets the requirements of national environmental protection.

The VU aggregate system enjoys the feature with intensity, friendly environment, large-scale automation has brought new development opportunities for sand and stone aggregate, dry mixing, commercial mixing, pipe pile, cement products, and other mining industries.

Compared with the traditional sand making equipment, VU aggregate system has significant advantages.

High Environmental Protection: to solve the pollution problem of traditional Sand making Enterprises/mining manufacturer.

The full-closed conveyance, production and negative pressure design of dust-removal shall be equipped with a humidifying stirrer to ensure that the water content of the finished sand is qualified, and the production site is free of dust.

Powder storage and brittle material monitoring and automatic telescopic discharge design to ensure that there is no overflow in the process of stone powder transport.

Hongxing Machinery adopts the Full dry production and screening process to ensure dry and clean stone powder, zero sewage, zero silt discharge.

Production spot from Zimbabwe customer, limestone crushing by hydraulic cone crusher

- 500-600 tons sand production line in Zimbabwe

- Material: limestone

- Finished product: gravel, fine sand

- Production capacity: 500-600 tons / hour

- Finished product size: 0-5mm, 5-10mm, 10-20mm, 20-31.5mm

- Finished product use: high-grade railway, highway, municipal and other infrastructure construction.

The foreign customer has been working with Hongxing Machinery for many years. With the market demand for stone materials increasing significantly, the customer once again contacted Hongxing to create a high-performance, high-intelligence, high-environment crushing sand production line. At present, the production line is stable in production, large in output and good in grain size. Once the tower boutique sand is launched, it is in short supply!

VU aggregate optimization system has become environmentally friendly

The storm of dust control in sandstone mines nationwide is prevailing now, and the VU aggregate optimization system has become environmentally friendly.

The continuous high pressure on environmental protection, coupled with the key pollution control of this dust hazard, for the sand and gravel aggregate industry, transformation and upgrading is an inevitable choice.

Green mine requirements for dust emission from sand and gravel industry

The construction of green mines has risen to the action of national. Under the background of the industrial civilization transferring to ecological civilization, the construction of green mines is the general direction, the big principle, the big logic! Saving economy, environmental friendliness and harmonious mining are the development model of green mining. Especially for the Hongxing Machinery.

In the process of mining and sand and gravel production, dust emission should meet the requirements of GB16297; for areas with strict environmental protection requirements, more effective measures should be taken to control dust emissions and meet local environmental protection requirements.

Hongxing company has established a dust-detection network and evaluation system, prepare a detection-control plan, and regularly organize third-party monitoring and self-monitoring for the detection and control objects.

Dust-control system in mining exploitation and sand production should follow the source control, process coordination control, end monitoring, system linkage and integration of management ideas to achieve environmental protection and energy-saving and clean production.

The mining area should be equipped with the sprinkler, high-pressure sprayer and other equipment to suppress and reduce dust from unorganized discharging dust, and water fog humidification, dust removal, and the drilling technology should be adopted to collect dust in the process of the air return of gas pipeline.

High-efficiency dust-removal devices should be installed in loaders, crushers, sieving machines, shaping machines, sand making machines, conveyor ports and so on.

Common configuration of aggregate in production lines

Generally speaking, the configuration of the aggregate production line needs to be combined with the user’s working conditions, time production, finished product size, energy consumption, etc. And there are the common equipment combination forms of the aggregate production line:

1, Fixed jaw crusher + cone crusher + sand making machine + auxiliary equipment (feeder, conveyor, hoist, etc.);

2, Jaw crusher + impact crusher + sand making machine + auxiliary equipment;

3, Hammer crusher + impact sand making machine + auxiliary equipment;

Combination of three

In addition, the impact rock crusher used for crushing brittle materials. As one of Hongxing series like Vertical Shaft Impact Crusher(shorted from VSI) is widely used for crushing of hard and brittle materials, such as rock, grinding material, refractory material, cement clinker.

The advantages of finished aggregate products processed by the aggregate production line

1, It has a good particle grading, small voiding rate, which can save the amount of cement.

2, It has stable physical and chemical properties and has better durability.

3, It is containing an impurity, which will not affect the condensation of cement, and can effectively improve the service life of engineering buildings.

4, The aggregate processed by machine has a higher hardness, and the lifting effect is more obvious.

The above is the introduction of aggregate and the production process of aggregate. If you are considering investing in sand and gravel aggregate production line and ask about price issues, please contact Hongxing Machinery, we will customize the production line according to your needs.