A customer from Nairobi named Alex asked our 24-hour online service, looking for cone crushers with good performance and excellent operation level. The requirements of cone crushers he wanted are as below:

- Small to medium size

- The size of crushing stone is roughly one-meter diameter or slightly more like boulders

- The materials tend to be 100kgs to 300kgs size

- The specifications of different types of hydraulic cone crushers

- The yield of the crushing machine ranges from 160t-250t per hour

So what advantages does hydraulic cone crusher have? Today we will introduce to you!

There are varieties of rock stone crushers in the market, including fixed jaw crusher, portable rock crushers, steel crushers, ore crusher, etc. As a new type of crushing machine, hydraulic cone crushers have advanced high-power, high production rate, and large crushing ratio. Besides, they also have superior working efficiency and strong ability to crush, which is conducive to the exploitation of all kinds of rocks and mines.

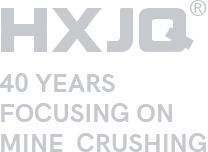

The advantaged design of this crushing machine and its superior performance manufactured by Hongxing machinery are the main causes of its promising prospect in the crushing industry. There are different modes of hydraulic cone crushers machine in Hongxing machinery, including single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, hydraulic cone crusher, and compound cone crusher. In addition, hydraulic cone crushers can be also named concrete crushers according to the materials crushed by cone crushers.

Several models of hydraulic cone crusher

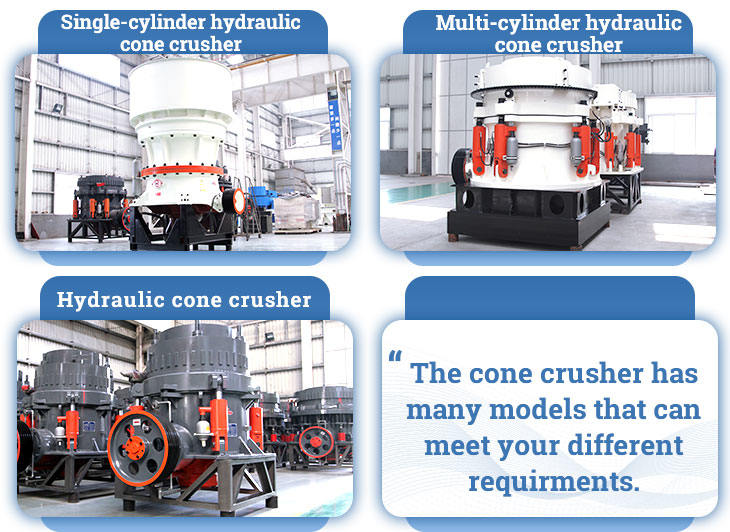

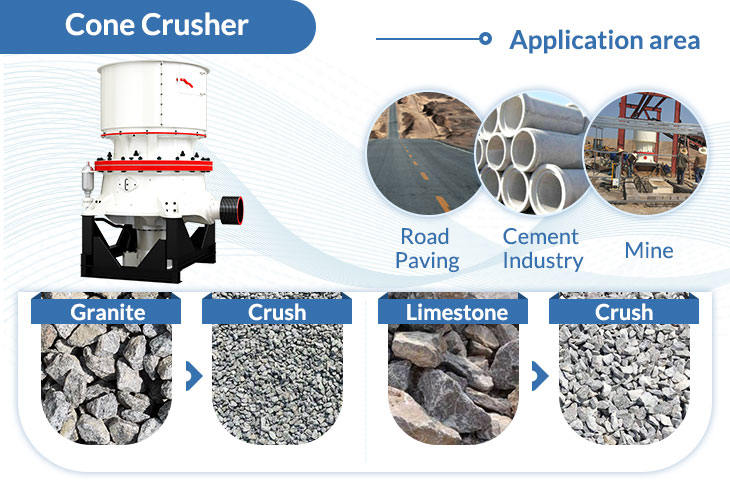

The cone crushers are widely used in many fields, mainly including mining, building, cement industry, and metallurgy engineering, etc. In China, the most common application fields of the cone crushers tend to be cement industry, road paving, and mining, accounting for about 31% in the whole crushing industry. At present, the single-cylinder hydraulic cone crusher is the most advanced crusher machine among the four types of cone crushers.

Compared to traditional spring cone crushers, hydraulic cone crushers have more outstanding advantages. They are reflected in many aspects, mainly including the producing capacity, working efficiency, operation costs, working principle, and the crushing machines’ maintenance, etc.

Six Advantages of Hydraulic Cone Crushers

- Large crushing ratio and high producing efficiency

The hydraulic cone crusher is a perfect combination of crushing stroke, crushing speed and shape of the crushing chamber. In this way, the higher rotation speed and stroke will be combined to improve cone crushers’ power rating and crushing capacity, and the crushing rate and production efficiency are also promoted.

- Less consumption of vulnerable parts and low operating costs

The hydraulic cone crushers have a simple structure, advanced crushing principle, technical parameters, reliable operation, and low operating cost. All components of the cone crushers are wear-resistant, so the general service life can be increased by more than 30%.

- Laminated crushing and excellent shape for finished grain

By adopting the special crushing cavity designed by the principle of intergranular lamination and the matching rotation speed, the selective crushing of the material will be realized, which is different from the traditional single particle crushing. This kind of crushing principle promotes the proportion of the fine material and the cube content. Besides, the needle-shaped material will be also reduced.

- A high degree of automation and less halt in the process of operation

Hydraulic adjustment of the discharge opening and overload protection will greatly improve cone crusher’s operation level, making it easier for maintenance, more convenient to operate. In the process of crushing, the traditional cone crusher may encounter the iron or stones with high hardness, which leads to abnormal operation.

In this case, the hydraulic cone crushers can pass the iron block through the crushing chamber, thus the machine can be hydraulically top and automatically discharge, which greatly reduces the trouble of manual discharge in the spring cone crushers.

- Thin-oil lubrication and longer service life

The hydraulic cone crushers’ design of the unique thin oil lubrication system greatly improves their service life. The high-performance and non-contact of the labyrinth seal improves the reliability of dust blocking, which fundamentally eliminates the common malfunction such as the mixing of the oil and water.

- Easy to repair and operate

All parts of the cone crushers can be disassembled and maintained from the top or the side. The moving cone and the fixed cone are easy to assemble and disassemble, and it isn’t necessary to disassemble the frame and tighten the bolts. Therefore, the cone crusher can replace the liner more conveniently.

The hydraulic motor will optimize the crushing production efficiency. Besides, the hydraulic cone crushers manufactured by Hongxing machinery possess higher production capacity and better production shape, truly creating more value for users.

At present, the intensity of mining is gradually increasing. In the exploitation of natural mineral resources with artificial value, the most important thing is the crushing of ore. The processed ore is used in various industries such as metallurgy, construction, and chemical industry. With the expansion of mining demand and infrastructure construction, the demand for sand and gravel materials and related crushing machinery has increased sharply.

Therefore, the market for cone crushing has broad prospects. However, most clients don’t know enough about the difference between the single-cylinder cone crushers and multi-cylinder hydraulic cone crushers. The difference between the two types varies a lot.

Our customer Alex tested our hydraulic cone crushers of differents types and he was very satisfied with our equipment

The Differences Between the Single-cylinder cone crushers and the Multi-cylinder hydraulic cone crushers.

- The comparison of discharge opening adjustment devices

Single-cylinder cone crushers: during normal operation, the oil pump is used to fill in or drain the spindle hydro-cylinder. In this way, the spindle will be moved up and down to adjust the discharge port size. This type of adjustment will be difficult for discharge port to lock when breaking the iron ores.

Multi-cylinder hydraulic cone crushers: adjusting the adjusting cap by hydraulic pusher or hydraulic motor can drive the adjusting ring to rotate in the support sleeve. In this way, the adjustment effect can be well achieved. The advantage of this type of adjustment is that the discharge port will be easy to lock.

- A comparison of crushing components

Single-cylinder cone crushers: the single-cylinder hydraulic cone crusher is similar to the spring one. The main shaft and the moving cone are combined and carried by the bowl-shaped tile. Therefore, the main shaft and the moving cone will support the base, and the eccentric sleeve drives the main shaft to provide the crushing force.

Multi-cylinder hydraulic cone crushers: its main shaft tends to be short and thick, and its diameter is long. It can stand directly on the frame and directly be supported by the frame that provides high bearing capacity. The eccentric sleeve will directly drive the moving cone to provide the breaking force.

- The comparison of actual production

When crushing the soft ores and weathered ores, the single-cylinder hydraulic cone is more outstanding. While when crushing the ores with medium and high hardness, the performance of multi-cylinder hydraulic cone breaking tends to be more excellent.

In the case of fine crushing for medium and high hardness, multi-cylinder cone crushers for sale can produce more qualified products under the same specifications. Generally speaking, the higher the hardness, the difference between the two types will be greater.

- The comparison of maintenance

The single cylinder cone crusher has a simple structure and reliable performance, which means it has a low failure rate and low production cost (the simpler the mechanical system structure, the failure rate will be lower, and the reliability will be higher).

The top or side of the multi-cylinder cone crushers can be disassembled and assembled, and the repair is quick and convenient: all the parts can be disassembled and maintained from the top or the side, and the moving cone and the top cone can be easily disassembled without disassembling the frame and fastening bolts, so the daily replacement will be more convenient.

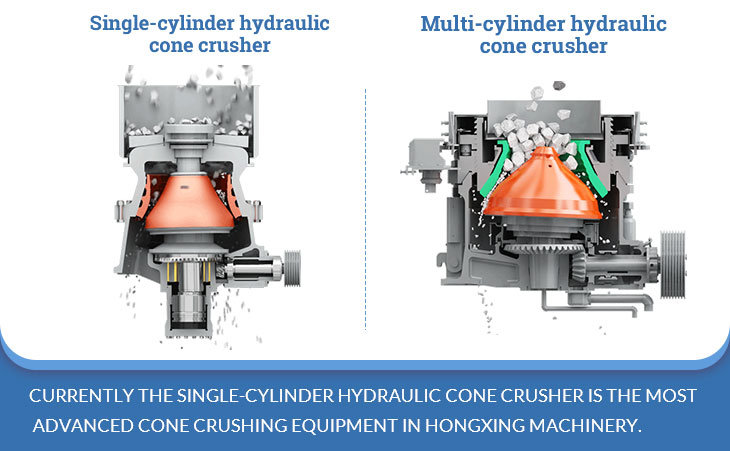

Different Types of Cones Crushers for Sale

| Specification | Model | Diameter (mm) |

Max feeding size (mm) |

Width (mm) |

Processing capacity (t/h) |

Total weight (t) |

Dimensions (L×W×H) (mm) |

| Φ600 | PYB600 | 600 | 65 | 12-25 | 40 | 5 | 2234×1370×1675 |

| PYD600 | 35 | 3-13 | 12-23 | 5.5 | 2234×1370×1675 | ||

| Φ900 | PYB900 | 900 | 115 | 15-50 | 50-90 | 11.2 | 2692×1640×2350 |

| PYZ900 | 60 | 5-20 | 20-65 | 11.2 | 2692×1640×2350 | ||

| Φ1200 | PYB1200 | 1200 | 145 | 20-50 | 110-168 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 100 | 8-25 | 42-135 | 25 | 2790×1878×2844 | ||

| Φ1750 | PYB1750 | 1750 | 215 | 25-50 | 180-360 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 185 | 10-30 | 80-210 | 50.3 | 3910×2894×3809 | ||

| Φ2200 | PYB2200 | 2200 | 300 | 30-60 | 420-700 | 80 | 4622×3302×4470 |

| PYZ2200 | 230 | 10-30 | 130-410 | 80 | 4622×3302×4470 |

As you see from the sheet, there are many types of cone crusher machine in Hongxing Machinery. And the price of cone crusher for different types is also different, a different yield of crusher machine also leads to different prices. Feel free to contact us, we will give you the price list according to your demands. Besides, we have specialized engineers who design a production line for you!