Types of construction waste

Construction waste refers to the muck, waste concrete, waste masonry, etc., generated in production activities such as demolition, construction, decoration, and repair. According to component classification, construction waste can be divided into the muck, concrete block, rubble, brick and tile fragment, waste mortar, mud, asphalt block, plastic, metal, bamboo, and wood, etc. These materials are of no help to the building itself, but they need to be dealt with accordingly, so as to achieve what we called “deal project construction”. Because it is a whole process from building to waste recycling, the consideration of its links is more important.

Several types of construction waste

Global Construction Waste Statistics

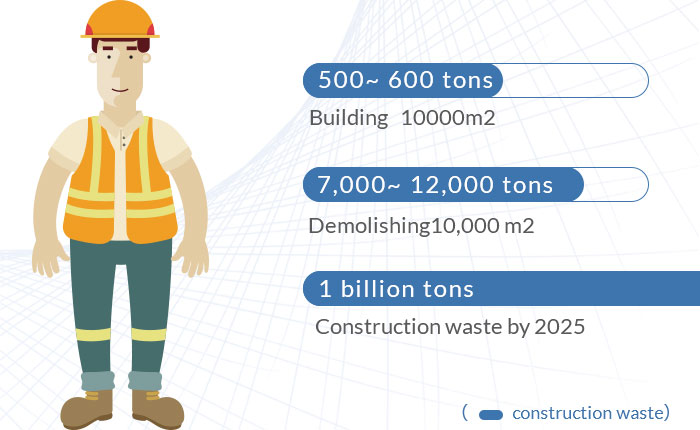

About one-third of the world’s energy is spent on buildings. According to statistics, 500~ 600 tons of construction waste will be caused by every 10,000 square meters of buildings, while the demolition of 10,000 square meters of old buildings will produce 7,000~ 12,000 tons of construction waste. According to the Transparent Market Research Report, the amount of construction waste produced worldwide will almost double to 2.2 per year. By 2025, it will reach 1 billion tons, according to the building and demolition recycling company.

What disasters does the construction waste bring to people

Disposal of construction waste is often a safety issue. In December 2015, a pile of construction waste caused a landslide in Shenzhen, China, which killed more than 70 people and displaced 900. The slide also demolished many buildings, including 33 factories, workers’ living quarters and apartments. Due to the construction boom in the area, the Chinese government has piled up more than 10 waste yards for the rubbish it causes. According to the New York Times, some analysts have blamed the landslide on China’s construction boom and local officials’ reluctance to enforce rules on the construction waste disposal.

https://www.theguardian.com/

In the United States, Texas officials are working to address the trash problem caused by last year’s hurricane Harvey in the Houston area, according to “Today’s Waste News” report. The federal emergency management agency says it will take years to clean up the area, and the Texas environmental quality commission has abandoned some solid waste regulations – air quality, emissions, wastewater and hazardous waste storage – to speed up the cleaning process.  https://communityimpact.com/

https://communityimpact.com/

In Minnesota, construction waste is affecting groundwater, according to the Bristol Herald Courier. Because construction waste from landfills is not included in the state’s solid waste regulations, the Minnesota pollution control agency (MPCA) is pushing for stricter standards for dismantling landfills that do not form a barrier between sediment and groundwater. County officials across the state, however, are resisting proposals to tighten regulations until the agency can determine exactly what is polluting groundwater.

https://www.desmoinesregister.com/

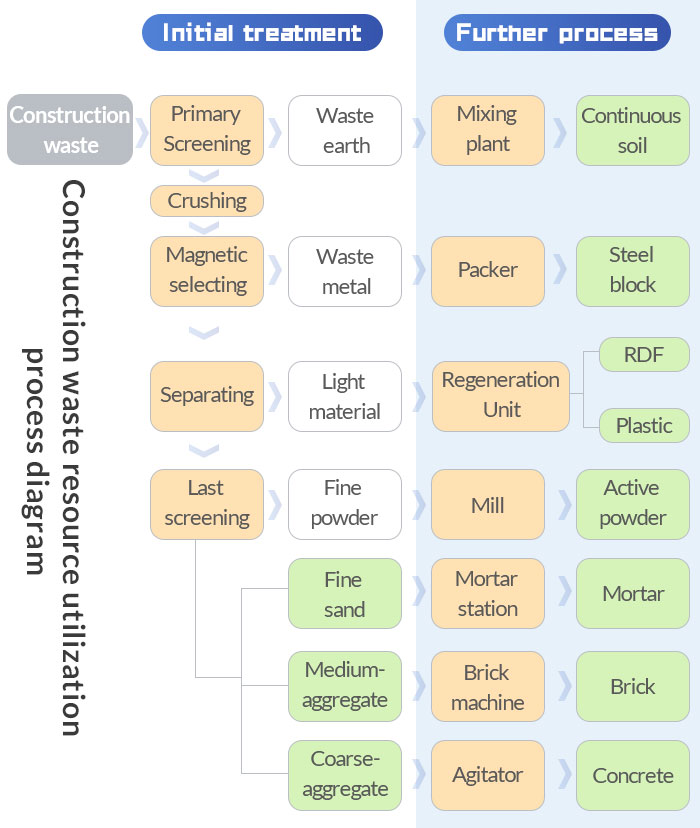

The recycling of construction waste

How to make construction waste brick?

Construction waste brick is a concrete block produced by crushed and sifted construction waste and cement as the main raw material and adds a small amount of sand and coal ash. And the strength of which exceeds the national standard by nearly 20%, which can save resources and protect the environment. It is an important measure to promote the structural adjustment of building materials industry, the comprehensive utilization of resources and environmental protection so as to realize the sustainable development of building materials industry on the road of a circular economy.

Are these bricks harmful to human health?

The brick performance depends on the characteristics of raw materials and molded machinery, and the product is tested by the national wall Roofing material Quality Inspection Center. Besides, its porous brick and standard brick respectively meet the requirements of JC943-2004 and NY/T671-2003 standards, thus can be safely applied to the construction project. In addition, after analysis, the performance of the product is superior to ordinary concrete perforated bricks and standard bricks in terms of bulk density and water absorption. The production method makes the structural properties of the raw materials unchanged, and the bulk density and water absorption are intermediate between the sintered product and the non-sintered product, as well as the thermal performance. Therefore, the dry shrinkage and thermal conductivity of concrete are smaller than the general concrete products, which is very beneficial for construction use.

How to make concrete from construction waste?

Producing concrete from a recycled aggregate of waste concrete can save 62% of limestone resources and reduce CO2 emission by 20%. In addition, high-performance recycled aggregate concrete can also comprehensively utilize coal ash, slag and other industrial waste residues, and at the same time, it can also solve the treatment problem of a large number of industrial waste residues and secondary pollution to the environment. Secondly, the recycling of waste concrete is conducive to the protection of arable land and ecological environment, which is of great environmental significance.

The recycling of waste concrete has good economic benefits. First of all, disposal and use of waste concrete in place or nearby can greatly reduce the production cost of finished products produced by waste concrete recycling and obtain good economic benefits. If the waste concrete is treated and used locally and nearby, the cost of loading, unloading, handling, transporting can be effectively reduced, thus greatly reducing the cost of recycled aggregate. Secondly, the recycling of waste concrete can save a lot of waste removal and disposal costs. Waste treatment must take into account the government’s policies and regulations, and comprehensively analyze the relevant costs of urban waste treatment according to the distance of garbage sites.

The construction waste can be crushed by both semi-portable crusher and tracked crusher

What’s the best construction waste management?

In the initial treatment of the garbage generated in the building, because many building structures are not concentrated, resulting in a lot of construction waste is also not concentrated. Therefore, when setting up the factory, the dispersion of construction waste should also be considered, so as to improve the treatment efficiency. Otherwise, it will take a long-distance and time to transport, which will not only increase the cost of transport but also lead to secondary pollution. Therefore, in the current international market, portable rock crusher is favored by developed countries such as Japan, Germany, the United States, the Netherlands, etc., all choose semi-portable crusher or tracked crusher to complete the dealing of urban waste.

At the site where construction waste is generated, people can initially dispose of it. The treated recycled aggregate is then transported to the aggregate deep processing center to complete the corresponding treatment. This will not only reduce transportation costs but also reduce the impact on the environment. It has two processes, screening and crushing, which greatly simplifies the process and reduces the cost of infrastructure investment and operation. Besides, it also has advantages of highly efficient energy-saving, compact structure, low height, small size, lightweight and large production capacity. Due to the wear-resisting steel, high strength and long service life, it can break materials with high hardness.

HXJQ portable rock crusher production spot(from our customer)

Six advantages of portable rock crusher

- The mobile crushing station can be used for a hill-climbing operation to meet crushing requirements of mines, hydropower stations, coal mines and other projects.

- The products of mobile crushing plant are light in weight and small in volume, which is more conducive to entering the construction area and provides more flexible space and a reasonable layout for the overall crushing process.

- The recycled aggregate produced has a good particle shape, which is conducive to being recycled.

- Mobile crusher saves fuel, with fuel-saving rate up to 25% and it can be used for both oil and electricity.

- The mobile crushing station is convenient for transportation, and the crawler can walk without damaging the road surface. It is equipped with multi-functional equipment and has a wide range of adaptability;

- The mobile crushing plant is equipped with a Power unit — optimal design, which eliminates the complex site infrastructure installation operation of separate components and reduces the consumption of materials and working hours.

In a word, construction waste is not really waste, but the “gold” in the wrong place. After being sorted, removed or crushed, most of the construction waste can be reused as renewable resources and turned into treasure.