What is limestone?

Limestone is a carbonate rock with calcite as the main component. It sometimes contains dolomite, clay, and detrial minerals, in different colors like gray, grayish white, payn grey, yellow, light and brown-red with small hardness. And it also can reveal a strong chemical reaction with diluted hydrochloric acid.

How is limestone formed?

Limestone is mainly formed in the shallow sea environment. According to the different ways of forming, there are various types of limestone including granule limestone (formed by flowing water or sedimentation ), bioskeleton limestone and biochemical limestone. As for biochemical limestone, when in a biochemical limestone, the calcium carbonate is locked into the fossil shells and skeletons of marine organisms. While in a chemical limestone, the calcium carbonate is in the form of calcite mineral crystals.

From its structure, we can get bamboo-like limestone, oolitic limestone, mink limestone, and lumpy limestone, etc. The main chemical composition of limestone rock is CaCO3, which can be easily dissolved. That’s why areas of limestone are stone forests, karst cave or collectively known as karstic topography. The main component of limestone is calcium carbonate which can also be dissolved about 50mg in one liter of water containing carbonate dioxide.

What kind of rocks can be called limestone?

Since the formation of limestones is related to biological effects, coral, shell and algae limestone are called bio-limestone. But if limestone is chemically precipitated to calcium carbonate (CaCO3) in aqueous solution, it is called a chemical limestone just like ordinary stone and siliceous limestone and so on.

note:image from Google

Over 20 uses of limestone

limestone is a very important industrial material in specials sectors like metallurgy, building materials, chemicals, light industry, construction, agriculture, etc. With the development of the steel and cement industry, the importance of limestones is further enhanced. Cement is a mixture of limestone and clay, being made by high-temperature calcination. Glass mixed with quartz sand, soda, and limestone, is made by high temperature melting. Iron-making uses limestone as a flux to remove gangue and raw lime is often used as slag-making material to remove sulfur or phosphorus in steel-making. Calcium carbide( the main ingredient is CaC2) is obtained by the reaction between lime and coke in the electric furnace.

After a few steps of chemical reaction among salt, limestones, ammonia and other raw materials, you can get soda ash and that process is called Solvay method. By utilizing the caustic method (reaction between lime and soda), you can make caustic soda. Bleach is created by the chemical reaction between pure slaked lime and chlorine. Using limestones chemical processing, we can get calcium chloride, nitrate, sulfate, and other important calcium salts. Lime can also be used as a water softening agent for removing the temporary hardness of the water. Besides above, limestone is processed into purer powdered calcium carbonate, which is used as a filler for rubber, plastic, paper, toothpaste, cosmetics, etc. Soda lime made from lime and caustic soda can be used as an absorbent for carbon dioxide while quicklime is used as desiccant or disinfectant. In agriculture, lime can be used to produce a mixture with sulfur and pesticides like Bordeaux. In addition, people can use slaked lime to neutralize the acidity of the soil, improve soil texture, supply the calcium required for plants and protect trees by brushing the trunk with lime. Just like an old saying in China that food is the paramount necessity for people, limestone is the grain of the cement industry or lifeblood for cement production. Cement cannot be produced without limestones, which means that people who own limestone resources will dominate the development of the cement industry. At present, the battle of the cement market in China can also be called the war of limestone resources. Therefore large enterprises often regard limestone mining as one of the strategic measures to strengthen themselves. Limestone is widely used in the history of human civilization because of its wide distribution and easy access in nature but it is a non-renewable resource. Therefore, with the continuous progress of technology and Nanotechnology, the application field of limestone will be further broadened.

Limestones can be applied in many industries

How to process limestones into cement?

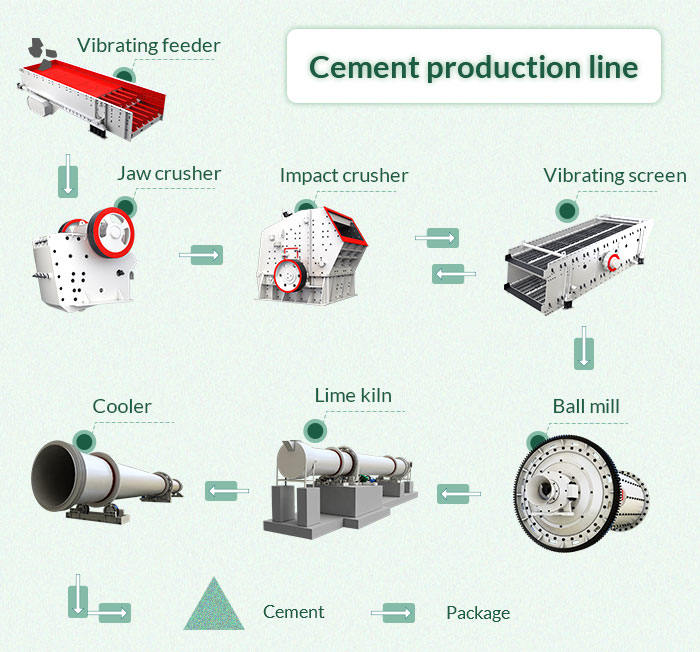

The specific process of producing cement-making from dry limestone:

1.crushing work

In the cement production process, most of the raw materials such as limestone, iron ore, coal, etc. should be crushed at first. Limestone is the key raw material for producing cement because of its larger granularity, higher hardness. To get various sizes of crushed limestone, you can use the coarse crushing machine like fixed jaw crusher or secondary crusher like impact crusher. Also, limestones can get rid of excessive pulverization. Based on the suitable crusher, limestone processing next work will be easier. The limestone crushing production line process is roughly described as follows: bulk material of the limestone passes through vibrating feeder, being transported to the jaw crusher for primary crushing. Then crushed materials are transported by the belt conveyor to the impact rock crusher for secondary crushing or fine crushing. Next, the crushed limestone is screened by vibrating screen. Last, the unqualified larger granular limestone is returned to the impact rock crusher again for tertiary crushing and the qualified materials are classified into according to the different stockpiles, which will be shipped directly to the construction site.

2. Cement material preparation

In the process of cement production, grinding work takes up more than 60% of the power of the whole plant, among which raw material grinding takes up over 30%, coal grinding about 3%, cement grinding about 40%. Reasonable selection of grinding equipment and technological process, optimization of process parameters, correct operation and control of the operating system are the most significant to ensure product quality and reduce energy consumption.

3.Raw material homogenization

In the process of new-type dry cement production, stabilizing raw material composition into the cellar is the premise for stabilizing clinker. The raw material homogenization system is the final check.

4. Preheat decomposition

The preheating and partial decomposition work of raw materials by the preheater can improve the production efficiency of the kiln system and reduce heat consumption. Preheat decomposition sets decomposition furnace between preheater and rotary kiln and a raised flue at the end of the kiln. Therefore, The heat release from raw fuel combustion and heat absorption from carbonate decomposition can immediately conduct in the rotary kiln, thus increasing the decomposition rate to over 90%. The pre-decomposition technology which has a series of excellent properties like high efficiency and low consumption is a technical leap in cement calcining process.

5. Burning of cement clinker

After preheating and pre-decomposition, the raw materials go into the rotary kiln for clinker firing. Then they are further and rapidly decomposed into materials, which are required for cement clinker making. Finally, with the increase of material temperature, the minerals will become liquid phase thus generating a large amount of clinker.

6. Cement Grinding

Cement grinding is the final process of cement manufacturing and also the process that consumes most of the electricity. Its main process is to grind the cement clinker into the appropriate particle size and certain size distribution. Besides, cement grinding can also enlarge the hydration area and accelerate the hydration, thus meeting requirements of cement condensation and hardening.

7.Cement packaging

After above all, you are into the last step. Usually, there are two delivery methods of cement packing: bag and bulk.

Sincere advice

Since the cement is so close to our daily life, the market of limestone or limestone mining is prosperous. When developing the industry of limestone mining, investors should be prudent for selecting the simplest process and qualified machines. Under such a fierce market, the ways to improve competitiveness are reducing the production cost and producing more qualified limestone products.