Allen, a customer from India, who was interested in lime kiln and he consulted our servicers to know about the relevant equipment. Here are his requirements for the equipment.

- The yield should be 1000-2000TPD

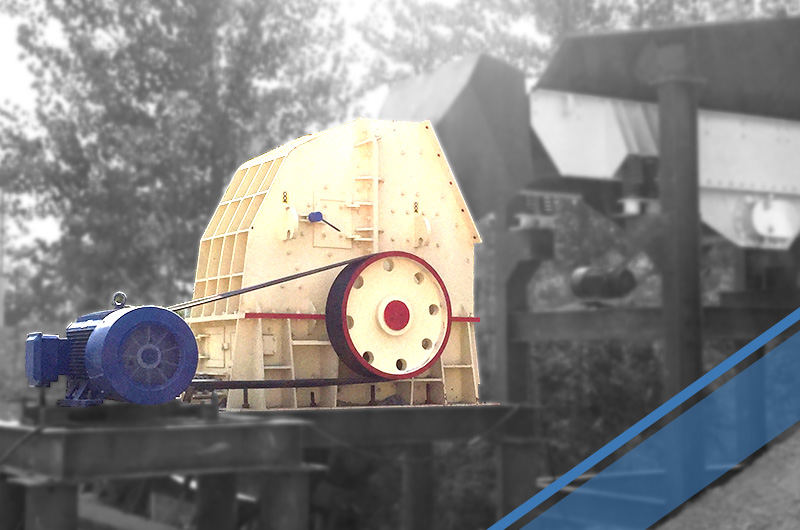

- Hammer crushers will be his first choice

- The price for the hammer mills for sale

Our salesman gave him detailed information about the hammer crusher. He was very satisfied with our equipment

The hammer crusher is a kind of crushing equipment for crushing materials in the form of impact, which is divided into two types: single rotor and double rotor. The single rotor is divided into two types: reversible form and irreversible form. At present, single-rotor hammer crushers and ring hammer crushers have been widely used.

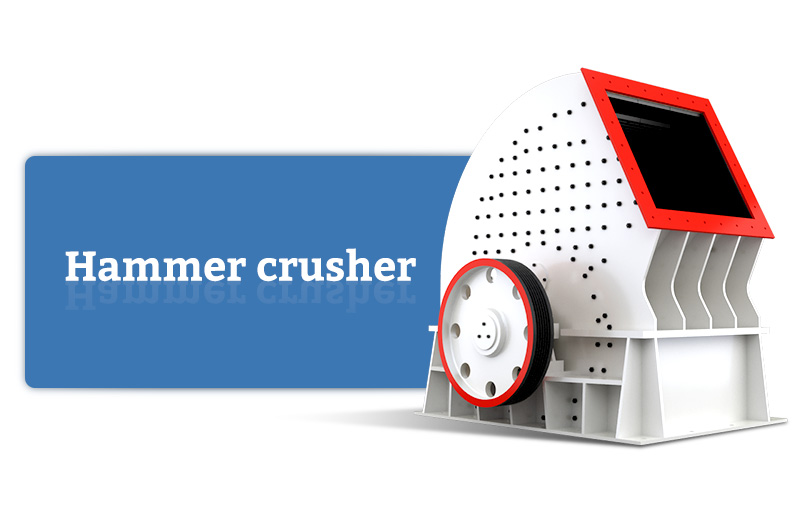

Besides, hammer mills can directly crush materials with a maximum particle size of 600-1800 mm. Therefore, the hammer mills for sale are suitable for crushing medium-hard materials such as limestone, slag, coke, coal and other materials in cement, chemical, electric power, metallurgical and other industrial sectors.

The hammer crusher manufactured in Hongxing Machinery has received good comments from our customers

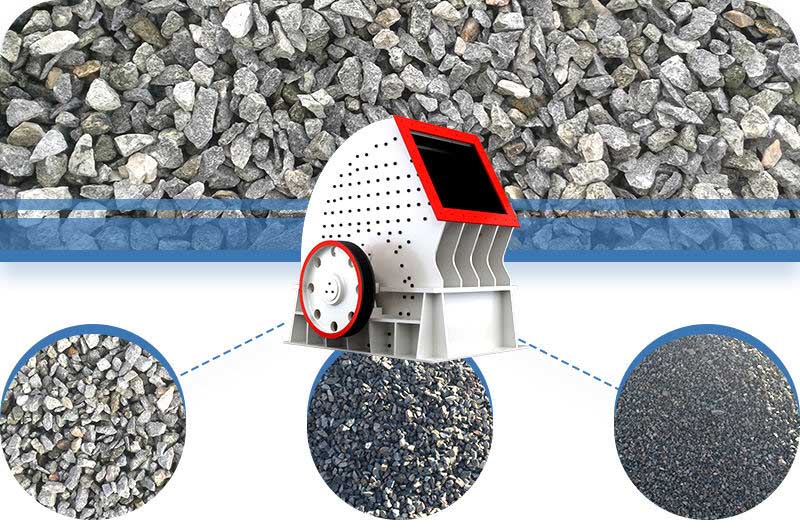

The advantages of hammer crusher

The advantages of the hammer crushers are large crushing ratio, high production capacity, less powder phenomenon, low energy consumption, simple structure, and easy for operation and maintenance. The hammer mills for sale are suitable for crushing various medium hardness and brittle materials, such as limestone, coal, salt, white Asia, gypsum, alum, brick, tile, coal gangue and so on. The compressive strength of the materials to be crushed by hammer crushers should not exceed 150 MPa.

When it comes to its applicable industry, this hammering machine is mainly used in cement, coal preparation, power generation, building materials, and compound fertilizer industries. It can crush raw materials of different sizes into uniform particles, which is beneficial for the next procedure to process because of its reliable mechanical structure, high production efficiency, and good applicability.

Hammer crushers are also used to crush paper, broken asbestos cement, and waste of wood with strong fiber structure, elasticity, and toughness. In addition, the hammer crusher can be used not only for crushing production lines, sand production lines, but also for conical crushers in beneficiation production lines.

The hammer crushers’ operation principle

Several rows of hammers are mounted on the main shaft of the hammer crushers. A pin shaft is bored in the pinhole of the circumference, and the hammer is hinged between the rows of hammer bodies by the pin shaft. If the hammer is worn, the working surface can be changed. There are two trapped pin holes on the hammer body. The distance from the center of the pinhole to the axis of rotation is different to adjust the gap between the hammer and the stringer.

In order to prevent the platinum body and the hammer from swaying, fix the hammer body and the lock nut at both ends of the hammer body. The two ends are supported on the rolling bearing, and the bearing is bolted to the casing. The spindle and motor are directly connected by a flexible coupling. In order to make the rotor run smoothly, one end of the main shaft is equipped with a flywheel.

The arc-shaped discharge screen is installed under the rotor, and both ends of the stringer are mounted on the beam, and the direction of the arrangement of the beam is perpendicular to the direction of movement of the rotor. The purlin gap is formed by the convex portion in the middle of the purlin in order to facilitate the discharge of materials. The slit is gradually enlarged downward while being inclined to the direction of rotation of the rotor.

Matters needing attention in the using process of hammer crushers

Correct operation and maintenance are of great importance for the service life of hammer crushers for sale. The crusher machine which is in good condition will also improve the crusher efficiency and production capacity.

Before the crushers working, remove the grid and take out the pieces of material and some debris that was not broken when broken. And in the process of working, the size of the materials should not exceed the specified size, otherwise, the production efficiency of the crushers will be significantly reduced and even the rotors may stop running. Besides, it is not allowed to adjust the gap between the rotor and the screen and open the rear wall of the delivered cabinet.

In the case that the product granularity does not meet the specified requirements, the following measures should be taken:

- Change the gap between the rotor and the screen.

- Adjust the worn hammer or replace the new hammer.

- Change the speed of the rotors(a relatively high speed can get a relatively fine material).

The working environment of the hammer mill tends to be bad. Therefore, special attention should be paid to the bearing’s lubrication and seal. In addition, the shaft temperature should not exceed 60~70 °C. If it is over temperature, the hammer crushers must be stopped to cool it and find out the cause. If the moisture content of the raw material is large, the sieve should be cleaned and inspected regularly.

Regularly re-select the grid to change the gap between the screens so as to change the crushing ratio. After the hammering machine stops, the workers should clean the dust of the outer parts, remove the materials stuffed in the grid, and check and tighten all the connections and sealing devices to determine the availability of the hammerhead, screen, liner and drive belt. When replacing the hammer, the rotors should be kept a balance to avoid violent vibration.

Hammer crusher’s main fault and its maintenance

- The hammer crushers will vibrate strongly at the initial moment of operation.

Cause: The rotors’ balance test was poor after replacing or exchanging the hammer.

Method: Remove the hammer head or re-select the hammer head (selected by weight) so that the total weight of each row of hammers is equal to the total weight of the hammers on the opposite side.

- There is a knocking sound in the hammer crushers.

Cause: There are several causes for this problem: the fixing of the lining plate may tend to be loose; the hammer head knocks on the lining plate; the hammer head, the bolt shaft or the disk is damaged; or the bearing cap is loose.

Method: Check the fixing of the lining; check the gap between the rotor and the screen; replace the damaged parts; check and tighten the bearing cap.

- the bearing is hot (The hands can not stand when touching it for 1-2 seconds ).

Cause: Insufficient lubrication, dirty oil or damaged bearings.

Method: Check the oil quantity. If the bearing continues to heat up, you can change the lubrication oil. If it is invalid after changing the oil, the bearing must be repaired.

- The rotation speed of the rotors reduces, and therefore the crusher will be stopped by the materials.

Reason: The feeding is not uniform, and the crusher is overloaded periodically; the transmission belt slips and the sieve is blocked.

Method: Remove the cause of uneven loading; tighten the belt and clean the sieve.

- The particle size of the broken material increases.

Reason: The hammer head is worn out, the screen bar is damaged, and the sieve is blocked by the materials.

Method: Replace or adjust the worn hammer head, check whether the sieve is intact and easy to use.

- As long as the material is fed, the hammers’ current will rise and remain high; when not feeding, the current will gradually drop.

Cause: The material is too wet, causing the liner to stick to the materials, and the hole of the sieve plate is blocked, which causes the crushing effect to be reduced, and the materials cannot be discharged from the sieve plate in time after crushing.

Method: At this time, some hard materials can be thrown into the hammer crushing machine. If the hard material method cannot be solved, it indicates that the sticking phenomenon is serious and can only be shut down for cleaning.

This picture is from our customer, Allen. He made a good comment on our hammer crusher

- The hammer crusher does not feed much, but the current is very high without much current fluctuation.

Cause: It may be that the hammer head, the lining plate and the sieve plate are seriously worn, resulting in a large distance between the hammer head and the sieve plate so that the qualified materials cannot be discharged in time.

Method: We can adjust the gap by the means of replacing the hammer head, the lining plate, the sieve plate the meet the standard.

- The discharge particle size becomes larger, but it still meets the requirements of raw material particle grading.

Cause: Probably because of the serious abrasiveness of hammer head and lining plate or overused sieve plate, we cannot get the ideal crushing effect.

Method: Check worn parts and replace them immediately. If the block material appears in the discharge, the sieve plate may be partially damaged and should be replaced immediately.

- Everything is normal when the vehicle is started without load, but the speed of the rotor of a feedstock will immediately reduce, and even downtime will occur.

Cause: It may be that the conveying belt is too loose, so the belt should be adjusted to make it tight.

Method: When the V belt is stationary, it is better to press the thickness of 1-2 V belts, or daub rosin powder or belt grease to the belt to reduce the belt slip phenomenon.

- The current of the hammer breaker fluctuates too much.

Cause: The feed is not uniform, or there are large blocks in the materials.

Method: Ensure that the working current fluctuation range of the hammer crushers should not exceed 20A.

- The hammering machine vibrates a lot

Cause: It may be because the weight of the hammer is very different.

Method: When replacing the hammer, try to use a hammer with the same weight and the same old and new level on one circumference. In addition, if the bearing is damaged and the anchor bolts are loose, the vibration of the hammer breaker is also large. If there is vibration during working, the hammer crushers must be stopped for inspection. It can’t work with a breakdown, otherwise, it will cause more damage to the hammer mills.

The price of hammer crushers

In short, the hammer crushers manufactured by Hongxing Machinery have excellent properties and good performance. What concerns you most maybe the price of the hammer crushers, different output requirements have different prices. If you’re interested in our hammering machine, please contact us and we will give you the most reasonable price and the crushing machine that meets your demand.