What is limestone?

Limestone is a common non-metallic mineral, which is also a trading name as a raw material mineral. Limestone is widely used because of its wide distribution and easy access in nature. As an important building material, the limestone has a long history of mining. In the modern industry, limestone is the main raw material for the manufacture of cement, lime and calcium carbide. In addition, the limestone is also an indispensable flux limestone in the metallurgical industry.

Limestone can be also used to manufacture glass, soda ash, caustic soda, etc., and the quicklime can be used to manufacture slag material, removing harmful impurities such as sulfur and phosphorus. In the agricultural industry, the application of slaked lime in the soil can neutralize the acidity of the soil, improve the structure of the soil, and supply the calcium required for the plant.

Generally, the chemical industry uses limestone to make important calcium salts such as calcium chloride, calcium nitrate, and calcium sulfite. In China, Xinjiang province is rich in limestone reserves. In view of the huge economic value of limestone mining, the limestone powder processing industry has been vigorously developed in recent years and has achieved good economic benefits.

With the continuous advancement of science and nanotechnology, the application field of limestone is being further broadened. Limestone is not only an indispensable raw material for the cement and steel industry but also widely used in water ash, smelting, cement, chemical, power plant desulfurization, and paper industries.

In addition, the limestone can be used as a substitute for plastics to make packaging materials, which brings environmentally-friendly benefits. The limestone market demand is increasing year by year, and it is one of the most dynamic environmental protection and green mineral resources in the 21st century. In recent years, the limestone powder processing industry has gradually become hot, and its application has achieved considerable economic benefits.

The limestone can be applicated in many fields

From the current demand for limestone at home and abroad, the annual demand for limestone in the world is about 1.2 billion tons, but 80% is for general use. High-quality limestone has a small market and a low market due to its low resources. In recent years, countries in the Asia-Pacific region have imported about 1.1 million tons of limestone from China each year because of insufficient domestic limestone resources.

According to experts’ predictions, domestic demand for high-quality limestone will increase by 250,000 tons per year and the Asia-Pacific region will increase by 300,000 tons per year.

From the perspective of the domestic market, the rapid development of the western region, urbanization, and new rural construction all have played a direct role in promoting the development of the metallurgical building materials industry, which will certainly stimulate the development of the metallurgical building materials industry. At the same time, limestone demand will increase.

From the perspective of the international market, China’s limestone mineral resources are rich, accounting for more than 64% of the world’s total reserves. Due to the limited limestone minerals in most western countries, cement production and limestone mineral resources have been restricted. Therefore, its dependence on Chinese limestone has gradually increased, and the export market continues to be optimistic.

Judging from the resource situation, the large limestone mines have been basically monopolized by large cement companies and metallurgical enterprises, and new resources are becoming less and less. In a sense, someone who owns limestone resources will occupy the future cement and steel market.

Four rock crusher machines to process limestone

The physical properties of limestone are small hardness and high brittleness. The limestone has low silicon content and low abrasiveness. Limestone crushing is relatively easy and the production cost is relatively low. According to different applications, the limestone needs to be crushed into particles of different sizes, which requires a limestone crusher machine. As long as the appropriate process configuration and crushing equipment selection are adopted in the crushing process, a good crushing effect can be obtained.

In combination with the principle of “crushing more and less grinding” in the limestone production line, it is necessary to produce the best particle size in the stage of limestone crushing. There are several types of rock crusher machine can process limestones, such as fixed jaw crusher, impact rock crusher machine, hammer crusher machine, and hydraulic cone crusher machine.

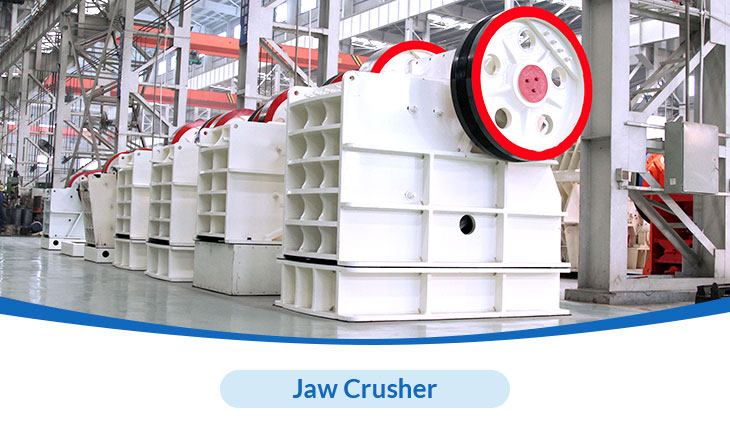

- The fixed jaw crusher is the most common rock crusher for sale at present, and it is also the earliest stone crusher that appears in people’s field of vision. HXJQ fixed jaw crusher machine has a remarkable effect on the limestone crushing and can crush large pieces of limestone.

The fixed jaw crusher machine is very convenient to operate and maintain, and it is very easy and quick to replace parts, saving a lot of replacement time. In addition, the fixed jaw crusher machine has low production cost and high output, which is very suitable for the primary crushing of limestone.

- The hammer crusher is also suitable for the crushing of limestone. It can directly crush large limestone to a particle size of less than 20 mm. The crushing effect is excellent and the limestone after crushing tends to be uniform. Therefore, the hammer crusher machine is widely used on the market.

Even the hammer crusher machine continuously working for long hours, the frequency of crushing failure tends to be low, saving customers a maintenance cost and reducing maintenance time, which has increased the economic benefits for the company to a certain extent. Stable operation, high output, and strong adaptability are the biggest advantages of the hammer crusher machine.

- The impact rock crusher machine has a unique working mechanism and structural design features. In terms of performance characteristics, the impact rock crusher machine has obvious technical advantages compared with the hammer crusher machine. The impact rock crusher machine has the advantages of small volume, large processing capacity, and good economic benefits.

Compared with the hammer crusher machine, the impact crusher machine has a larger crushing ratio and can fully utilize the high-speed impact energy of the entire rotor. In the process of actual production, the impact rock crusher is also the main rock crusher of the limestone crushing production line. The crushing characteristics of the impact rock crusher are remarkable: uniform discharge granularity, cubic discharge, low fine powder and dust.

The impact rock crusher has several advantages to process limestone

- The hydraulic cone crusher is a very good limestone crushing device, mainly used for the crushing of limestone. The floor space of the hydraulic cone crusher machine is small because of its advanced structural design, saving a part of capital construction for the customer.

Compared with other rock crushers for sale, the hydraulic cone crusher has the advantage of environmental protection. At the limestone crushing site, almost no dust can be seen, reducing pollution to the environment. In addition, the hydraulic cone crusher machine has the advantages of superior performance, affordable price, high output, and low failure rate.

How much is the rock crusher for sale to process limestone?

Common limestone crushing line equipment includes fixed jaw crushers, impact crushers, belt conveyors and vibrating screens. This is in terms of overall device configuration. However, different types of rock crushers will be configured according to customers’ actual needs. The fixed jaw crusher is generally selected as primary crushing. If the second-stage crushing needs to be configured according to customers’ actual demands.

Feedback picture from our African customer, a limestone production line

Through analysis and comparison, the four stone crusher machines have their own advantages in crushing limestone. In the end, which stone crusher should be selected depends on the customer’s actual needs. If the amount of limestone material processed tends to be relatively large, it is recommended to select an impact rock crusher. For the price of limestone crushers, the price of different types of rock crushers for sale is different.

For example, the fixed jaw crusher is divided into CJ series European version fixed jaw crusher, PEX series fixed jaw crusher, and the hydraulic cone crusher can be divided into single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher, full hydraulic cone crusher, etc.

The price of rock crushers for sale with high-yield tends to be high. HXJQ technicians will design the most suitable rock crusher for sale according to each customer’s needs and budget. The corresponding stone crusher will be configured according to the production site and production demand. In addition, our technicians will personally install and debug the machine to provide a one-stop service for customers.