The sand machinery is suitable for crushing soft or medium hard or extremely hard materials. It is widely used in various ores, cement, refractory materials, aluminum earth clinker, corundum, glass raw materials, etc. In the engineering field, the sand machinery is a piece of ideal production equipment for asphalt concrete and cement concrete aggregates.

HXJQ sand machinery working principle

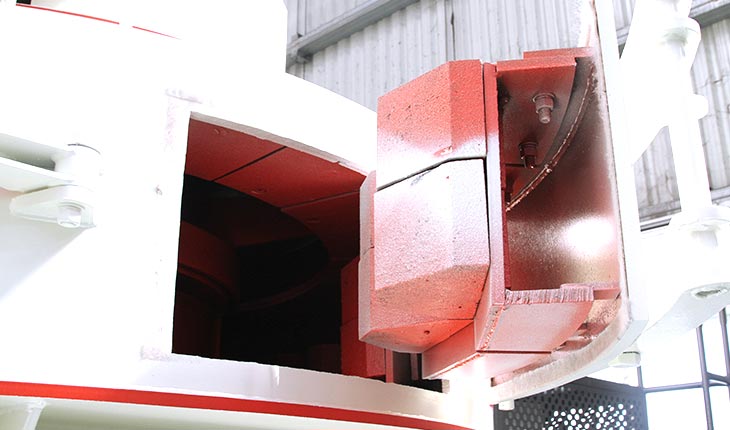

The material enters the sand machinery from the feeding hopper, and the material is divided into two parts through the feeder. One of the two parts is inserted into the high-speed rotating impeller from the middle of the distributor, then the material will be rapidly accelerated in the impeller, and can reach hundreds of times of gravity acceleration. Next, the material will be ejected from the three uniform flow channels of the impeller at a speed of 60-70 m/s.

After that, the material is impacted and crushed by a part of the material falling from the periphery of the distributor, and then impacted together on the material lining in the vortex cavity. In this way, the material is rebounded by the material lining, impacts obliquely upward to the top of the vortex chamber, changes its direction of motion, deflects downward, and the material emitted from the impeller runner forms a continuous material curtain. Such material is subjected to two or even multiple chances of impact, friction and grinding and crushing in the vortex crushing chamber. The crushed material is discharged from the lower discharge opening.

During the whole crushing process, the materials are crushed and impacted by themselves, and are not directly in contact with the metal components, but are impacted and rubbed against the material lining, which reduces the angular pollution and prolongs the mechanical wear time. The ingenious airflow inside the vortex chamber self-circulates, eliminating dust pollution.

The new type of sand machinery uses a diamond-shaped combined impact block (scraping head) instead of the original integral hammerhead and square impact block. The impact blocks alloy is “hard but not brittle, tough and firm” and has good high-temperature resistance. The impact block is directly forged with imported high-quality alloy, wear resistance and toughness, which is at the leading level in China, greatly improving work efficiency, and the service life is 3-5 times higher than that of high manganese steel.

VSI sand machine is the second-advanced sand maker, while the most advanced tends to be the HVI sand machine

The advantages of sand machinery

- Simple structure, low cost

- Energy-saving, high crushing ratio

- With fine crushing and coarse grinding function

- The ability to pass non-crushed materials is strong, and the water content is small, reaching 8%.

- It can crush medium and hard materials (such as corundum, sintered aluminum vanadium, etc.

- Cube-shape, low iron pollution

HXJQ sand machine has simple structure, low cost, and high crushing ratio

How to maintain and protect the sand machinery?

- Rotor rotation direction

From the top of the device, it must be rotated counterclockwise. If it is rotated in the wrong direction, it will cause serious damage to the rotor. The two motors must be in the same direction of rotation. When the judgment is unclear, the V-belt can be removed to observe the steering of the two motors.

- Lubrication function

Sand machinery has unique operating conditions. Do not use different types of grease alternately. Consult the grease used by the factory, which is essential for long-term stable operation of the equipment.

- Removal of iron

The particle size of the mixed iron or feedstock in the feedstock is too large, which has a significant impact on the life of the throwing head. Therefore, people always remove the iron on the iron remover and check if the screen is damaged. For this purpose, a separator should be installed on the feed tape.

- Drive the tension of the tape

Proper tension is extremely important for long-term, normal operating conditions of the drive belt and is especially important for dual-motor drive equipment. If the current of one motor is lower than the current of the other motor, it may be caused by the difference in the tape tension of the two motors. After the new tape is idle for 30 minutes, the tension should be re-adjusted. After running the feeding operation for 8 hours, please adjust the tension again to eliminate the natural extension of the tape, otherwise, it will easily burn the tape.

- Dust control

Usually, during normal operation, the air turbulence in the crushing chamber creates an ideal dust collecting environment and does not require dust collecting equipment to reduce dust, but a large amount of dust is discharged when starting or stopping or insufficient feeding during operation. A water spray device can be installed at the discharge opening, and a lock associated with the motor can be turned on/off so that the sand machinery automatically activates the spray device to control dust emission when driving or stopping.

- Operation record

Detailed records of daily operation records, such as vibration values, upper and lower bearing temperatures, rotor stop time after shutdown, etc., play an important role in judging the operational failure of the equipment and ensuring long-term operation of the equipment.

Checking the crusher machine in a regular time is helpful to avoid sudden faults

Analysis of several common faults of sand machinery’s operation process

- The vibration value is too large

The upper limit of the set value of the vibration switch plays an extremely important role in the sand machine protection. When the vibration of the sand machinery reaches a certain limit, the vibration power should be used to cut off the power supply of the motor.

Main reason:

- There is uneven wear of the rotor, causing damage to the throwing head.

- There is uneven material in the sand machinery rotor.

- The damping pad has been damaged.

- The main bearing has been damaged.

Solution methods:

- Check the rotor wear and replace the corresponding throwing head.

- Turn off the sand machine to check the accumulation of materials in the rotor and adjust the feed rate.

- Replace the damping pad.

- Fasten the pulley sleeve.

- Replace the main bearing.

- Fasten the loose bolts.

- The upper and lower bearing temperatures are too high

When the meter shows that the bearing temperature exceeds the standard, the crusher machine should be stopped for inspection.

Main reason:

- The motor is overloaded for a long time.

- The main bearing is damaged. The operator should be familiar with the sound of the bearing when it is running. If the sound changes, especially if the sound is low, the bearing tends to be deteriorated.

- The bearing lacks grease.

Solution methods:

- Appropriately reduce the motor load.

- Replace the damaged bearing.

- Fill the grease.

- Unblock the grease drain groove.

- The ammeter is abnormal

The reason why the current is too large: the feed amount is too large, and there are too many accumulated materials in the crushing chamber or the machine base, the discharge hopper is clogged, so there is a mechanical or electrical failure.

Solution methods:

- Reduce the amount of feed

- Unblock the material, and find specific electrical problems.

The reason why the current is too small: the feed amount is too small, the drive belt slips or there is an electrical fault.

Solution methods:

Increase the amount of feed appropriately, replace the drive belt, and find specific electrical problems.

Customer's production spot in Indonesia

What parts should be checked for the safe operation?

- Check the current of the sand machinery:If the motor current is too large and the motor is overloaded, the feed amount should be reduced until the current value is normal.

- The power of the sand machinery is the electric motor, so there are certain requirements for the load of the voltage and transmission lines. Pay attention to the electrode quality when lowering the electrode and dropping the electrode for a few minutes. In addition, take various measures to prevent the electrode from being broken. Once a soft break of the electrode occurs, it must be processed immediately.

- Operate in strict accordance with the regulations. When there are uncrushed materials get into the sand machinery, it should be stopped running and clean the materials before production.

- At the same time, the sand machinery cannot be started running when there has been material inside, or the motor will be burnt out because the starting pressure of the motor is too large, and there may be other damages. What’s more, when the sand machine is about to end the work, it is necessary to confirm that the materials inside the sand machinery are completely removed.

- The sand machine uses car grease or 3# lithium base grease. Add the proper amount of grease for 400 hours of work. Open the spindle assembly to clean the bearing for 2000 operation hours. Generally, the new bearing should be replaced after the sand machine operates for 7200 hours.

- The tension of the transmission triangle tape of the sand machine should be adjusted appropriately to ensure the uniform force of the triangular tape. When the double motor is driven, the triangular tapes on both sides should be grouped and matched so that the length of each group is as uniform as possible. In this way, the sand machinery can be energy-saving and efficient.

- The sand making machine needs to stop regularly to observe the wear inside the impact sand making machine. It should be replaced or repaired in time after wear. When replacing the wear block, it should be replaced synchronously to ensure the same weight of the wear block.

- The normal operating temperature of the sandbox bearing box should range from 40 ° C to 60 ° C, if the temperature exceeds 70 ° C, indicating that the bearing box of the sand machine has certain problems. So the crusher machine should be shut down for maintenance in time.

sand making machine with the vibrating screen is heading towards the crushing site

How much is the HXJQ sand machinery?

There are several types of sand making machines, including VSI sand making machine, HVI impact sand machine, and vertical shaft impact sand machine crusher. Different types of sand machinery have different properties and performance. Therefore, the price tends to depend on the modes of the crusher machine. Contact us, we will give you the latest price list!