In order to enhance the maneuverability of the crusher machine, the portable rock crusher is designed and developed in combination with market demand. A portable rock crusher can be used for crushing rock, ore, block road asphalt concrete, construction waste, and other materials.

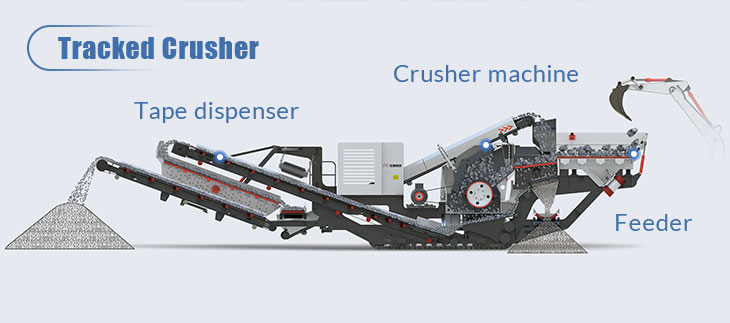

The portable rock crusher is mainly divided into the semi-portable crusher and tracked crusher. The most intuitive difference between the two crusher machines is that they use different walking modes. What are the similarities and differences between them? The characteristics and respective advantages of the two portable rock crushers are as follows:

The common advantages of two kinds of portable rock crushers

- Flexible moving and less operation time

Hongxing Machinery portable rock crushers can directly reach the mining site without being affected by the change of the worksite. It starts to work after the crusher machine being started in a short time. Due to the small size of the portable rock crusher, it is especially suitable for the narrow place of the crushing site. At the same time, it eliminates the cumbersome steel frame structure and the construction of the foundation, which saves a lot of time.

- Integrated assembling unit

The integrated unit equipment installation form eliminates the complicated site infrastructure installation work of the split components, reducing the material and working hours consumption. Besides, Hongxing Machinery portable rock crusher is a production line integrating the processing equipment such as receiving, crushing and conveying. The reasonable and compact space layout of the unit improves the flexibility of the station.

- Low material transportation costs

The portable rock crusher can process materials on-site without having to move the materials away from the site for further processing, which greatly reduces the transportation cost of materials.

- Flexible combination and full functions

According to the actual production requirements of the user, various combinations can be made to form different crushing process, which can be combined into a coarse crushing, medium crushing, and fine crushing system. In addition, these systems can be operated independently with great flexibility.

Two types of portable rock crusher have several common advantages

In addition to the above common features, the two crusher machines also have their own unique advantages, which will be compared from the following aspects:

Respective advantages of semi-portable crusher and tracked crusher

- Action force

Actually, the semi-portable crusher can’t be fully called a mobile crushing plant because its transitional movement relies on the semi-trailer head for traction, so it is not as powerful as the tracked crushers.

- Applicable venue

Because the semi-portable crusher is driven by a vehicle, so it is more suitable for the crushing of various sand and gravel materials such as construction waste, earth and stone works, urban infrastructure and road construction, etc.

The tracked crusher chassis adopts a full rigidity ship type structure, which has high strength, low grounding ratio, good passability, good adaptability to mountains and wetlands, and even can realize climbing work, so the tracked crusher is often used for some mining and open-pit mining environment.

- Working efficiency

When the semi-portable crusher is working, the hydraulic support legs under the frame are fixed, so the stability of the whole station is increased. The stability is the basis of the operation of the semi-portable crusher. Good stability enables the whole crusher machine to be operated on a large scale, which means that the semi-portable crusher can carry out large materials. Therefore, the working efficiency of the semi-portable crusher is extremely high. While the tracked crushers have a little weaker stability.

- Operation performance

The semi-portable crusher has a short wheelbase, a small turning radius, which will not damage the road surface, and can be flexibly driven on ordinary roads and working areas.

The tracked crusher uses the crawler to walk, enabling to realize in-situ steering. In addition, standard configuration and wireless remote control are equipped in the tracked crusher, making it easy to drive the crusher machine onto the trailer and transport it to the worksite.

- The finished product effect

The semi-open discharge system of semi-portable crusher is suitable for crushing construction waste containing a small number of steel bars. It has fine discharge, less pulverization, and good pellet formation, which is especially suitable for the production of environmentally friendly bricks. Therefore, the semi-portable crusher is often applied to construction waste treatment, and the recycled aggregate by construction waste has a good granular shape, which is favorable for recycling.

In summary, both the semi-portable crushers and tracked crushers have their own characteristics, which are selected according to the user’s production requirements. With the pursuit of efficiency and convenience, mobile rock crusher tends to be applied to in all walks of life.

Two feedback pictures from our customer on production site

So how to choose the most suitable portable rock crusher? There are many factors should be taken into account.

Several factors ought to be considered to choose a suitable portable rock crusher

- The crushing capacity required by the users

The portable rock crusher type will be very different because of the different processing capacity.

The processing capacity of the crusher machine will be affected by the conveying capacity of the feeder. For example, the processing capacity of the portable rock crusher is 450 m3/h, while the conveying capacity of the feeder cannot reach 450 m3/h, which will definitely affect the processing capacity of the crusher machine.

The maximum size of the feed size should also be taken into account when selecting the plate feeder. Because the width of the different plate feeders is limited, it should be slightly larger than the feed size so as to operate normally, otherwise, it will get stuck in the front of the hopper, which will be impossible to unload the materials into the crusher cavity.

The crushing capacity is also related to the volume of the hopper. If the hopper volume is too small, the feeder will quickly unload the materials into the crusher cavity, so the hopper will not have enough surplus materials. In that case, the truck cannot replenish the materials in time, which will affect the crusher machine processing capacity.

- Supporting equipment owned by the user

Before designing a portable rock crusher, it is necessary to have sufficient knowledge of the crushing equipment that the user has equipped in the open-pit mine. The main equipment associated with the semi-portable crusher is mainly electric shovel, truck, crawler truck or track bulldozer.

Electric shovel and truck are short-distance transportation vehicles. If their production capacity matches the processing capacity of the portable rock crusher, the crushing system formed will be operated normally, and the crushing capacity will be fully achieved the target processing capability. If a mismatch situation happens, there will be a waste of resources.

Tracked trucks and track dozers are the moving tools for portable rock crushers. When designing, the handling capacity of the handling tool should be taken into account. If ignoring this, the portable rock crusher will be a serious mistake.

- Site conditions for portable rock crusher

Most of the portable rock crushers are used in open-pit mines. In some areas, the winter temperature is low, so the portable rock crusher design should fully consider whether the materials have cold resistance.

In addition, the local earthquake level, wind power, and snow thickness should be also taken into account. The seismic load, wind load and snow load caused by these natural conditions will affect the steel structure. It depends on whether the material and structural characteristics of the portable rock crusher can meet the force exerted by these loads.

- The moving cycle of the portable rock crusher

The movement cycle of portable rock crusher is also very important. Some portable rock crushers should be moved once every 3-6 months, while some crusher machines should be moved once for 1-3 years. And the frame structure of the portable rock crusher can be determined from the movement cycle.

- Matching of the main equipment angle and distance of the crushing station

The most important thing in the design of the portable rock crusher is the mutual relationship between the main equipment, namely, feeder, crusher machine, and belt conveyor. The three kinds of equipment are closely related to each other.

The distance and height between the feed conveyor and the portable rock crushers are often determined by the fluidity and handling capacity of the raw materials. The feed conveyor is also angled to the horizontal plane for better control of material flow and layer thickness.

Generally, it is more reasonable when the angle is 15°, which will not affect the material flow thickness, and also saves motor power. If the angle is too large, the driving power of the feeder will increase relatively; if the angle is too small, the vertical height of the crusher machine and the belt conveyor will also be affected.

The price of semi-portable crusher and tracked crusher

Hongxing Machinery portable rock crusher for sale have different modes and production capacity, which will lead to different prices. Therefore, feel free to contact us, we will give you the most reasonable price according to your requirements. More importantly, Hongxing engineers will design a special production line that is suitable for your requirements.