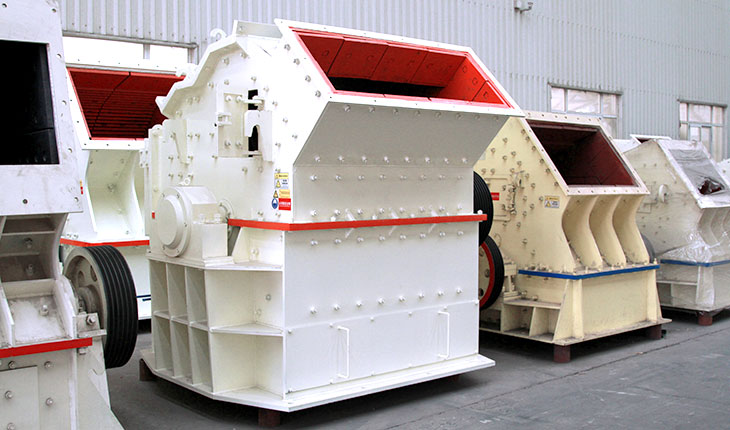

Tertiary crusher, also known as high-efficiency fine crusher, and concrete crusher. This kind of concrete crusher machine for sale has a wide range of applications and its performance has reached the international leading level.

HXJQ tertiary crusher machine is the most effective, practical and reliable crusher machine, especially suitable for processing abrasives, refractory materials, cement, quartz sand, steel sand, slag powder, copper ore, iron ore, gold ore, concrete aggregate, asphalt aggregate and other hard and brittle materials of fine and medium crush, which is a highly efficient, energy-saving gravel sand making equipment, and energy-saving 50% than the traditional fine crusher(concrete crusher).

The application of fine crusher in the field of ore mining is very frequent because the tertiary crusher machine has a good energy-saving effect, and it is widely used in railway construction, highway construction, airport construction, municipal construction, bridge construction, etc.

Therefore, environmentally-friendly and energy-saving fine crushers are more favored by people. HXJQ tertiary crusher is constantly improving in terms of performance, structure, design, materials, etc, promoting the development of the low-carbon economy.

HXJQ tertiary crusher machine for sale will be your best choice

HXJQ tertiary crusher machine for sale working principle

The tertiary crusher machine has a stable and reliable running performance, simplified process, simple structure, and convenient maintenance. In addition, the production capacity of the tertiary crusher machine tends to be large and the hammer part has a long service life. In this way, the investment in the tertiary crusher will be lower than that of traditional crushing equipment of the same scale by 35%-50%, and the output efficiency will be higher than that of traditional crusher machine of the same scale.

What’s more, the long-term operation and maintenance cost of tertiary crusher machine is also lower than the traditional scale crushing equipment. The tertiary crusher is a kind of crusher machine that proceeds continuous working. When the tertiary crusher starts working, the rotor will rotate at a high speed under the driving of the motor, and the material enters the first crushing chamber to be crushed. The hammer is impacted and broken, then enters the second finely divided cavity for pulverization, and finally discharged at the discharge port.

HXJQ tertiary crusher machine has many advantages

Matters needing attention in the operation process of tertiary crusher machine

- The inspection work before starting up the tertiary crusher is turned on mainly to check if all the components and bolts are in good fastening condition.

- The hammer is an important part of the HXJQ fine crusher machine. Due to its long-term beating effect, the hammer tends to be one of the most wearable parts. Therefore, the tertiary crusher hammer part should be checked or replaced frequently for daily maintenance.

- Check the lubrication status of each lubrication point of the crushing equipment and make sure that each lubrication point is in an ideal state. Professional cleaning grease is used for daily maintenance of mechanical lubrication points. When selecting lubricating oil, the operating environment in which the tertiary crusher is located should be fully considered. In general, change the lubrication oil when the tertiary crusher machine is operated for more than 900 hours or 6 months.

- When installing, cover the outer ring of the bearing with the same thing as the rotor shaft cone to prevent possible corrosion.

- Repair the wear between the crushing plate and the hammerhead of the concrete crusher. Adjust the distance between the crushing plate and the hammerhead, which is mainly by the back and forth movement of the supporting device of the concrete crusher’s crushing plate.

Both coarse crushing and fine crushing can be done by tertiary crusher machine

The similarities and differences of the ordinary stone crusher and tertiary crusher machine

From the name of the ordinary stone crusher and the tertiary crusher, it seems that the differences between the two crusher machine do not be very large. As a crushing machine, both of them are to crush the materials. However, in terms of the type of materials, the differences between the two crushing equipment tend to be very large. How to choose the most suitable crushing equipment? Here are the common features and differences of the two crusher machine.

Similarities of the two stone crusher

- The two crusher machines all belong to the stone crusher. Both of them can crush the materials in various ways. They have the characteristics of adjustable discharge size and can be applied to many different types of production lines. The ordinary crusher machine and fine crusher are all ideal for handling medium hardness materials and are easy to operate.

- HXJQ crusher machines(mainly include the fixed jaw crusher which also named lime crusher, portable rock crusher, impact rock crusher, hammer crusher machine, etc.) and the tertiary crusher are all environmentally friendly crusher machines, and the environmental property mainly reflecting that the working processing will not produce noise and will not cause damage to the environment. Both of the crusher machines are advanced products that conform to the development of the times and will make more contributions to the future mining industry.

Differences between the two stone crusher

- In the production process, the crusher machine also called “first-stage crushing”, which means that the ordinary crusher machine is often used as the first-class crushing machine, and the fine crusher is often called “secondary crushing”, that is, the fine crusher is often used for back-end equipment.

- In terms of material output, the output of the tertiary crusher is often finer than that of the crusher machine, but the production capacity of the crusher machine is much higher than that of the tertiary crusher machine. When selecting a stone crusher, the user needs to select a crushing machine that is more suitable for the needs of the production line.

The stone crusher machine and the fine crusher have many similarities and many different points. When selecting the equipment, it is necessary to compare the functions and yield of the two stone crusher, selecting the most suitable crusher machine under the advice of professionals.

Hongxing Machinery engineers will install the crusher machine for every customer in person

How much is the HXJQ tertiary crusher machine for sale?

HXJQ high-efficiency tertiary crusher is developed by absorbing domestic and foreign advanced crushing technology and combining with the specific working conditions of domestic cement industry, mining, mineral processing, and building materials enterprises. Its power-saving and consumption reduction is better than that of traditional crushing technology. The comprehensive effect is stronger than that of the hydraulic cone crusher machine.

At present, there are many manufacturers producing high-efficiency fine crushers in China, and the production technology and level tend to be different. Therefore, how to buy affordable stone crusher machine for sale has become a problem for many customers.

With a 40-year of professional production experience of various stone crusher for mines, HXJQ technology for producing high-efficiency fine crusher tends to be skillful. In addition, HXJQ is a self-produced and self-selling manufacturer. There is no external cost, so the price will be lower than other crusher machine manufacturer. The final price of HXJQ crusher machine will decide on the production capacity, and our engineer will design a special production line for you!