What’s the difference between crushed stone and gravel?

Crushed stone is one of the most common and accessible natural resources on the planet. The crushed stone is a little bit small and without a regular but sharp edge because it belongs to rocks and crushed by the crushing machine. It is one of the most popular materials for residential products like driveways and landscaping.

crushed stone is suitable for driveway

It’s a man-made product and usually contains a combination of natural stone, like limestone, granite, and trap-rocks. These stones are crushed to create the jagged edges we associate with gravel. Many homeowners prefer crushed stone because it’s available in a variety of sizes and colors, so they can achieve their desired aesthetic.

The primary difference between crushed stone and gravel is that gravel is not man-made. It forms naturally from large rocks, which erode over time, creating smaller rocks. As a result, crushed gravel is typically rounder and has a smoother shape than crushed stone.

Gravel has less carrying capacity than the crushed stone

Different effects when using them to pave a driveway

The differences between the crushed and the gravel mostly in the field of the construction. The gravel is kind of smooth and has no edges but after a long time eroded by the river, its hardness is not as good as that of crushed stone, which also determines that it is a low-strength stone in the building and driveway paving.

Besides, it will show the poor construction stability when being mixed with the cement to enhance the strength dut to the smooth edge and the weak hardness. For example, if there is a higher requirement for strength and load-bearing for the driveway, crushed stone is needed.

As for the crushed stones, there are many classifications, but the size of the stone will determine how it should be used. It could be used as the foundation of pavers and roads, fence drainage and concrete blocks. And the materials of the crushed stone can be easily found and crushed into any shapes and sizes according to customers’ demands.

The crushed stone can also be used for paving the driveway of the courtyard

Materials of Crushed Stone

Basically, the materials of the crushed stone are limestone, traprock, granite, argillite, quartzite. Although they are huge blocks at first, after the processing of different crushing machines at a different level, it’ll be crushed to the desired size. In general, the crushed stone has to get through the two or three levels of crusher which means it should be reduced by the primary crusher like PE jaw crusher then the secondary crushers like cone crushers or impact rock crushers and finally the tertiary crusher.

Crushed Stone Grades

The following list gives a rundown of crushed stone grades and their best uses. While there may be slight variances in the naming convention of crushed stone the following are the most common names and sizes:

| Name | Size | Application |

| Crushed stone #5 | Sizes are from 1″ down to fine particles | road and paver base |

| Crushed stone #67 | Sizes from 3/4″ down to fine particles | road and slab base |

| Crushed stone #1 | Sizes are from 2″ to 4″ | culvert ballast |

| Crushed stone #8 | Sizes from 3/8″ to 1/2″ | concrete and asphalt mix |

| Crushed stone #3 | Sizes from 1/2″ to 2″ | drainage and railroad projects |

| Crushed stone #10 | Screenings or dust | fabrication of concrete blocks |

| Crushed stone #57 | Sizes of about 3/4″ | concrete, asphalt mix, landscaping |

| Crushed stone #411 | A mixture of stone dust and #57 stone | driveway, patch holes in paved areas |

What’s the best size crushed stone for a driveway?

Crushed Stone #411

The final layer of a gravel driveway consists of smaller gravel blended with coarse rock dust, known as “fines”. Crushed stone #411, which is a mixture of #57 stone and coarse rock dust, is a good option for road top layer. This blend of small stones and rock dust will fit tightly together as the stones settle, forming a stable, solid surface that can stand up to heavy vehicles.

The crushed stone #411 is crushed by a mobile rock crusher

Why is crushed stone best for the driveway?

1) Style Versatility Although people may connect the crushed stone with the rural driveway which is so beautiful and full of the aesthetic, the fact of the matter is that it also contributes a lot to the driveway of the city and makes the road a large carrying capacity so that whether modern and funky or classic and elegant, crushed stone will fit the bill. 2) Design Flexibility Without any limitation is the most attraction s of the crushed stones. The crushed stone can be poured into any shape – no matter how irregular – so that your driveway can be just as unique as you are. 3) Affordability Many people want their selections of the materials for driveway are affordable and high- quality. Of all of the surfacing options for residential driveways, crushed stone is perhaps the cheapest.

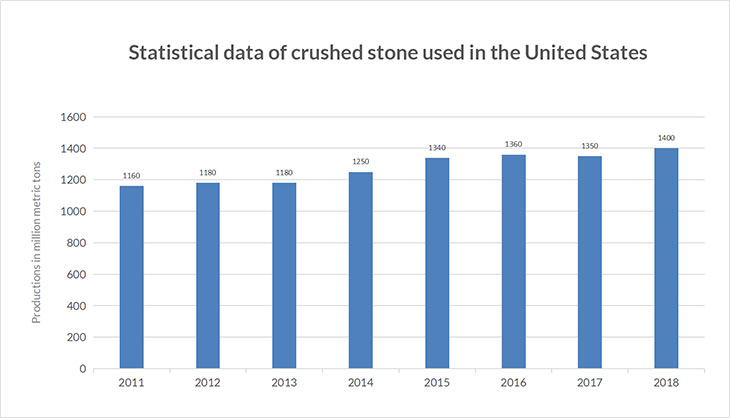

Statistical data of crushed stone used in the United States

According to the United States Geological Survey, 1.72 billion tonnes of crushed stone worth $13.8 billion was sold or used in 2006, of which 1.44 billion tonnes was used as construction aggregate, 74.9 million tonnes used for cement manufacture, and 18.1 million tonnes used to make lime. Crushed marble sold or used totaled 11.8 million tonnes, the majority of which was ground very fine and used as calcium carbonate. And the following chart also shows us the large quantity of crushed stone is a very important resource to develop the construction of the United State.

increasing number of the use of the crushed stone year by year in Amrecia